Steps Involved in Garments Production Process [Industrial]

Last updated on August 15th, 2023 at 10:49 pm

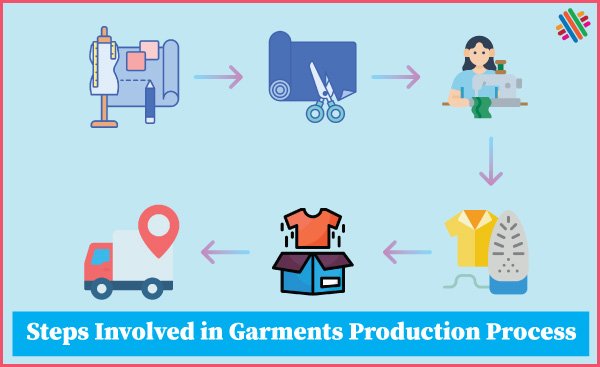

Garment manufacturing is a process by which a complete piece of garment is made. Fabrics, trims, and accessories are the basic raw materials for garment manufacturing. The quality of a garment totally depends on the quality of the raw materials and the manufacturing process.

Now we will see the process flowchart of garment manufacturing below:

Process Flowchart of Garments Manufacturing

Design or sketch

↓

Basic block

↓

Working pattern

↓

Sample making

↓

Approved sample

↓

Costing

↓

Production pattern

↓

Grading

↓

Marker making

↓

Fabric spreading

↓

Cutting

↓

Sorting and bundling

↓

Sewing

↓

Ironing or finishing

↓

Final inspection

↓

Packing

↓

Cartooning

↓

Send to Buyer or Dispatch

Brief Discussion

It is nothing but one kind of engineering art including all measurement of particular style.

Basic block

It is an individual component of garments without any design or style.

Working pattern

To make pattern for a particular style with net dimension.

Sample making

To make the sample according to the demand of the buyer is called sample making.

Approved sample

The sample which is approved by the buyer is called approved sample.

Costing

To determine cost considering fabric required, making a charge, trimming, profit is called costing.

Production pattern

To make a pattern for a particular style with net dimension along with allowance.

Grading

The process to grade up the approved sample according to dimension, i.e., S, M, L, XL, and XXL are called grading.

Marker making

To make the marker where the marker is a thin paper which contains all necessary pattern pieces for all sizes for a particular style of garments in such a way that fabric wastage would be the least.

Fabric spreading

Fabric spreading is a process in which piles of fabric is spread to get required length and width as per marker dimension.

Cutting

Cutting means to cut the fabric according to marker dimension.

Sorting bundling

To sort The fabric according to size is called sorting, and for each size, making the individual bundle is called bundling.

Sewing

Sewing is the process to join up the different parts of the fabric with the help of sewing needle or thread in manually or sewing machine.

Ironing or finishing

It is a process to get complete garments treated with steam ironing.

Final inspection

To inspect the fabric finally.

Packing

It is the process to pack the garments treated by polyethylene bag.

Cartooning

It is the process to keep the pack in hand paper bag for export, To minimize damage.

Send to buyer

When all the processes are done, then the garments are sent to the buyer.

You may also like: Animal Print Fashion and Trend that Never Lost