What is Weaving | A Short History of Weaving

Last updated on August 28th, 2023 at 11:56 pm

Weaving and Woven Fabric

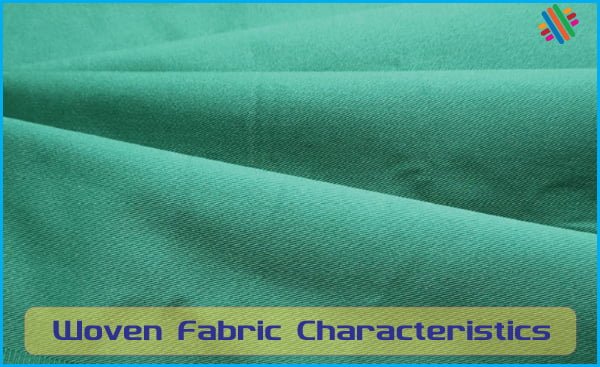

In general terms, a textile fabric may be defined as an assembly of fibers, yarns or combinations of these. There are several ways to manufacture a fabric. Each manufacturing method is capable of producing a wide variety of fabric structures that depend on the raw materials used, equipment and machinery employed and the set up of control elements within the processes involved. Fabric selection for a given application depends on the performance requirements imposed by the end use and/or the desired aesthetic characteristics of the end over, with consideration for cost and price. Fabrics are used for many applications such as apparel, home furnishings, and industrial.

The most commonly used fabric forming methods are weaving, braiding, knitting, tufting, and non woven manufacturing.

Weaving is the interlacing of warp and filling yarns perpendicular to each other. There are practically an endless number of ways of interlacing warp and filling yarns. Each different way results in a different fabric structure.

Weaving of yarns into a fabric is performed on a “weaving machine” which has also been called a “loom”. However, “loom” is more descriptive of a “shuttle weaving machine”. For shuttle-less “looms”, the term “weaving machine” is more appropriate since these machines are as sophisticated as any other machine that exists today. A typical modern weaving machine consists of up to 5000 parts, working together in a very precise manner. Although shuttle leans have been obsolete, reference is still made to them, for comparison purposes, when describing shuttle-less weaving machines.

History of Weaving

Weaving is probably as old as human civilization. One of the basic necessities of humans is to cover their bodies to protect themselves from outside effects (hot, cold) and look more “civilized” to the eye. Other reasons for development of different clothing throughout the history are social status, religious requirements etc. Clothing: trends depend on location as well. Historical findings suggest that Egyptians made woven fabrics some 600 years ago. Chinese made fine fabrics from silk over 4000 years ago. It is believed that the hand loom has been invented many times in different civilizations.

You may also like: Famous Silk Weaves

Weaving started as a domestic art and stayed as a cottage industry until the invention of the fly shuttle. The fly shuttle, invented in 1733 by Kay, was hand operated. in 1745, de Vaucanson made a loom, further developed by Jacquard, to control each warp end separately. In 1785, Cartwright invented the power loom which could he operated front a single point. In the early 1800s, looms made of cast iron, were operated by steam power. Power loom required stronger warp yarn, resulting in development of the fast sizing machine in 1803. In the 1830s, there were some 100,000 shuttle looms operating in England. The processing principles of these looms were pretty much the same as today’s shuttle looms.

In the early 20th century, improvements were made in the winding and warping of yarns. The looms were improved further, including warp tying machines and warp drawing-in machines. After the end of the World War 2, the modern textile industry began to emerge. Invention of synthetic fibers changed the scope of textile industry drastically. In 1930, an engineer named Rossmann developed the first prototype of projectile weaving machines. In 1953, the first commercial projectile weaving machines were shipped. Production of rapier and air-jet weaving machines started in 1972 and 1975, respectively.

The fundamental principle of weaving has recall progress has been on accelerating the conventional weaving process. Over a period measured in centuries the filling insertion rate, for example, has increased from a few meters per minute to over 2000 m/min. Major increases have been revealed at textile machinery shows. There are three major textile machinery shows in the world: ITMA which is held every four years in Europe, ATME-I held every four years in the US, and OTEMAS held in Japan. This machinery shows usually alternate with each other. The filling insertion rates of today’s conventional single phase weaving machines are approaching physical limits. Further major increases in performance can only be achieved with new technologies such as multi phase weaving machines.

Can I share this piece from you? It’s well-written advice worth passing on! My subscribers would want to read this too.