What are Stitched Double Cloths? Classification of Stitched Double Cloths

Last updated on September 6th, 2023 at 12:44 am

Definition

Double cloths are fabrics in which there are at least two series of warp and weft threads each of which is engaged primarily in producing its own layer of cloth, thus forming a separate face cloth and a separate back cloth. The two layers may be only loosely connected together in which case each may be readily identified as a different entity or they may be so intricately stitched or tied together that they appear to form a complex single structure.

The purpose of the construction may be entirely utilitarian, such as the improvement of the thermal insulation value of a fabric in which a fine, smart face appearance is necessary; or it may be aesthetic in intension for which purpose the existence of two series of threads in each direction improves the capacity for producing intricate effects dependent upon either color, or structural changes.

Classification of double cloths

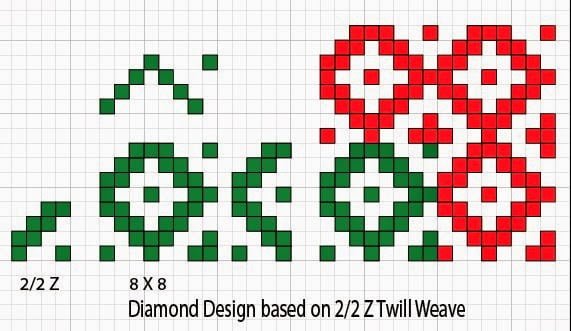

Most of the double cloths can be classified under well defined headings and the following list gives the principal structural types with the simple schematic diagrams in the figure illustrating the basic principle of each construction.

Self-Stitched Double Cloths

These fabrics contain only the two series of threads in both directions and the stitching of the face cloth layer to the back layer is accomplished by occasionally dropping a face end under a back pick or by lifting a back end over a face pick or by utilizing both of the above systems in different portions of the cloth. This type of structure and the three different methods of stitching are illustrated at the following figure:

Centre-Stitched Double Cloths

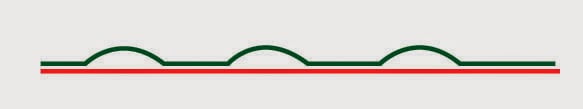

In these fabrics a third series of threads is introduced either in the warp or in the weft direction whose entire function is to stitch the two otherwise separate layers of cloth together. The center threads lie between the face and the back cloth for the purpose of stitching oscillate at regular intervals between the face and the back thus achieving the required interlayer cohesion as shown at the following figure:

Double Cloths Stitched by Thread Interchange

These structures are similar to the first category in as much as they do not contain an additional series of stitching threads. However, they are distinguished from the self stitched fabrics by the fact that the stitching of the face and the back cloth is achieved by frequent and continuous interchange of some thread elements between the two cloth layers. Thus, in some portions of the cloth the face ends may be made to inter-weave with the back picks and the back ends with the face picks as illustrated schematically at the following figure. The point at which the threads interchange represents the stitch points.

Double Cloth Stitched by Cloth Interchange

In this class of constructions the principle of the interchange is taken one stage further than in the third category and complete cloth layers are made to change places as shown at the following figure. As stitching between the two fabrics occurs only at the point of cloth interchange the degree of cohesion in this type of cloth depends on the frequency of the interchange.

Alternate Single-ply and Double-ply Constructions

In some fabrics the constituent thread components are occasionally merged together into a heavily set single cloth and occasionally are separated into distinct layers to form figure areas of open double cloth on the firm single cloth ground. Usually, the effect depends upon a degree of distortion as the crammed single cloth areas tend to spread out, thus affecting the appearance of the double cloth ‘pockets’. A cloth of this type is shown at the following figure.

End uses of Stitched double cloth

Double cloths are used as different types of decorative cloth such as – sofa cover, furnishing cloth, curtain fabric, bed cover, pillow cover and other home textiles. It is also used for the production of winter garments, quilts, belts, different types of industrial fabrics etc.

You may also like: Multi Component Fabric