Processing Flowchart of Cotton Yarn Manufacturing

Last updated on July 5th, 2023 at 11:57 am

A yarn is a continuous and uniform mass of fibres bonded together by the insertion of a twist. Yarns are the raw material of the fabric. The thickness of the yarn varies to a wide range. Normally, the thickness of yarn is expressed in terms of count. The count may be defined as the number which expresses the fineness or coarseness of yarn. The yarns may be spun from staple fibre or continuous filaments. Normally the majority of yarns are produced from staple fibre. To produce yarns from staple fibres, a wide range of machines are needed, called spinning machines.

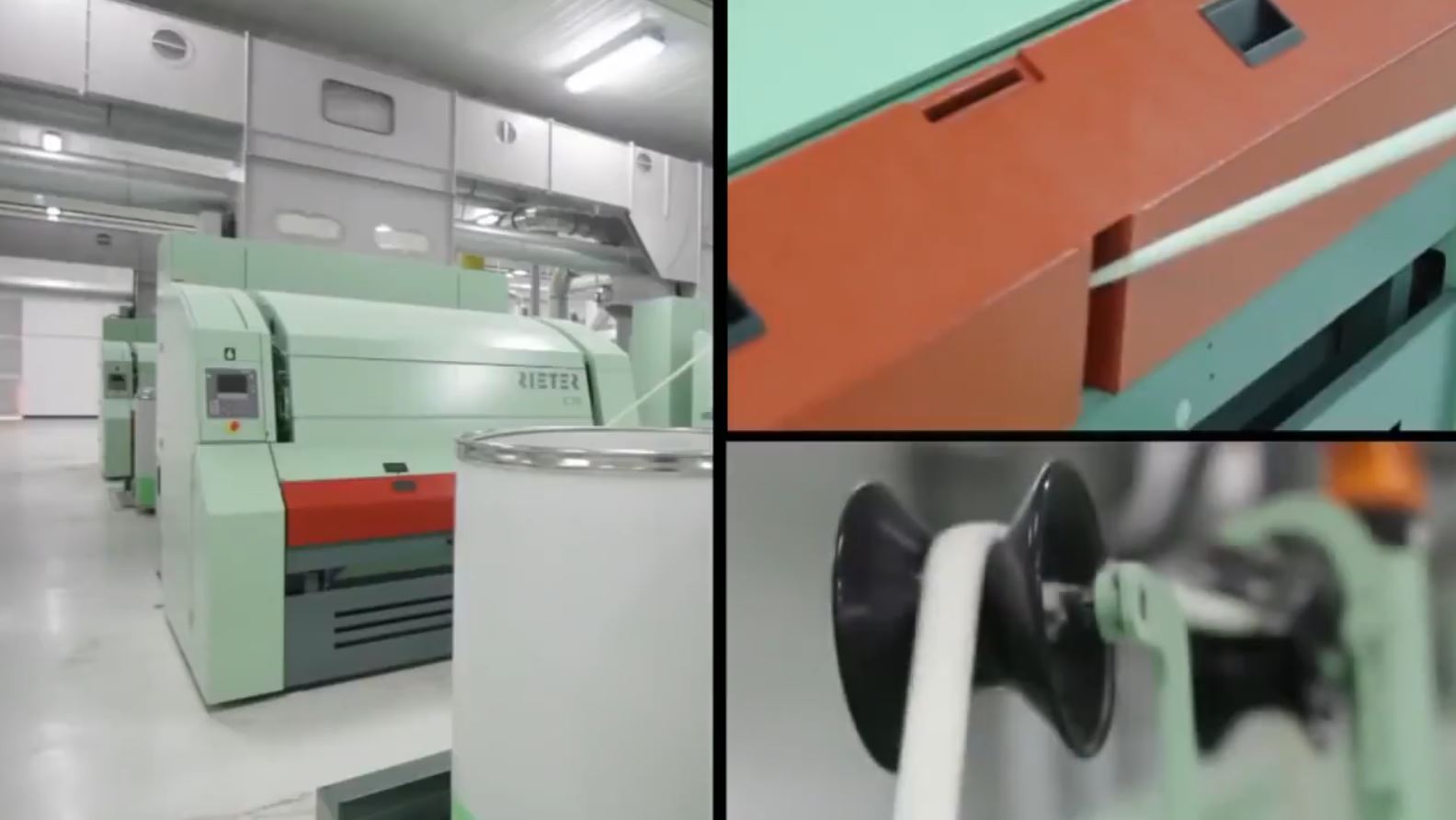

A process flow chart of spinning machines and stepwise process sequence for producing cotton staple yarn is shown below:

Cotton in bale form

↓

Blow room machine

↓

Carding machine

↓

Drawing machine

↓

Roving machine

↓

Spinning machine

↓

Cotton yarn

Now I’ll describe the stages in brief as follows –

wow ….. nice article with clear information

Thanks bro…Stay with my blog site.

Your very own commitment to getting the message throughout came to be rather powerful and have consistently enabled employees just like me to arrive at their desired goals.

Thanks for your help and for writing this post. It’s been great.

I want to thank you for your assistance and this post. It’s been great.