Definition, Objects and Operations of Simplex Machine

Last updated on August 17th, 2023 at 10:40 pm

Definition of Simplex

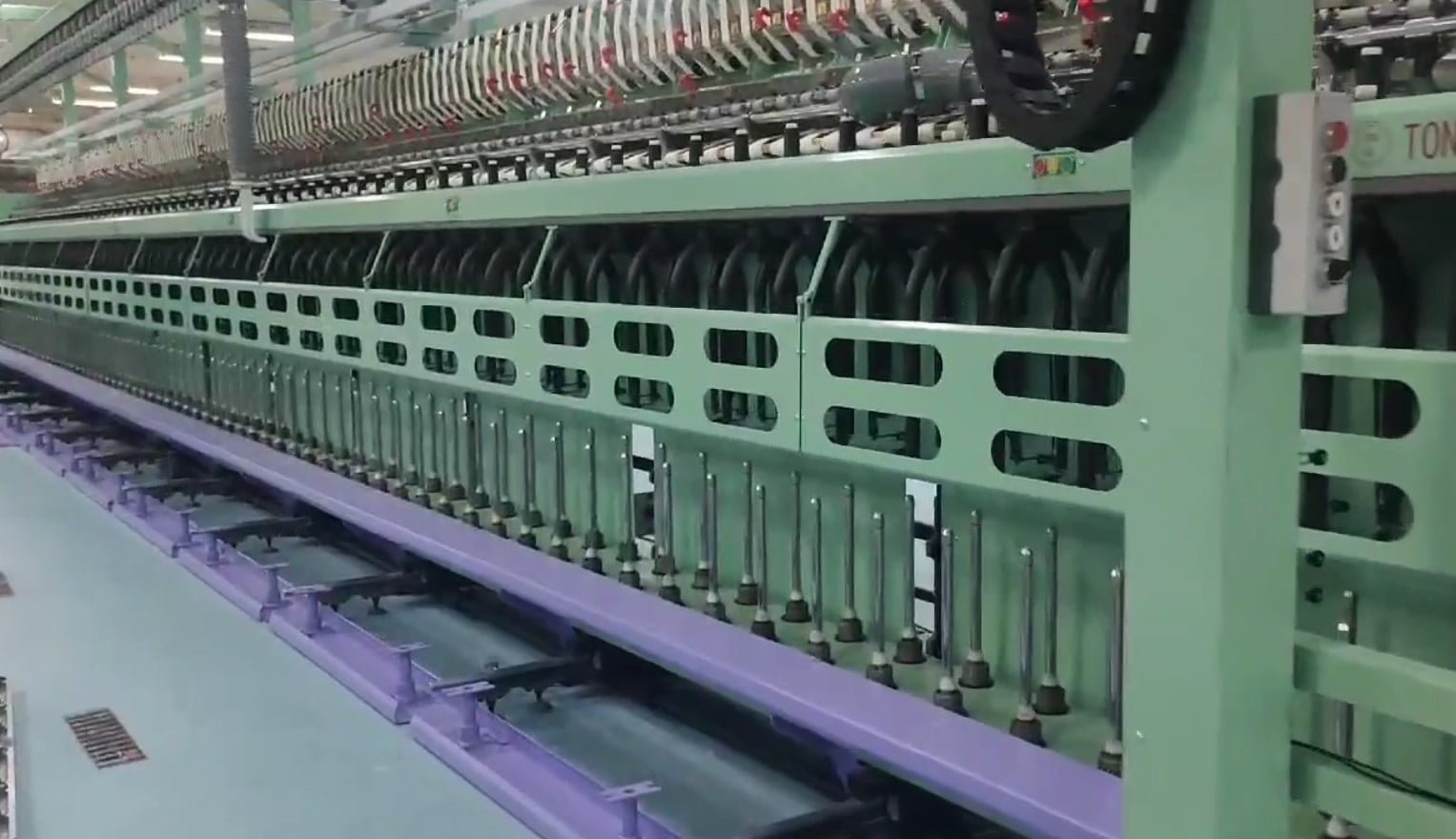

In yarn manufacturing system, simplex frame is situated after the comber. The sliver which is produced from the comber that is thicker and it is not suitable to feed into the ring frame directly to produce yarn. For this reason, drawn sliver is treated before entering into the ring frame. The commonly used simplex machine for cotton is flyer frame or speed frame. There are three basic steps in the operation of the roving frame – drafting, twisting and winding. These three basic steps are exactly the same as the basic steps required in spinning.

The machine where the sliver is subjected to one or more attenuating process and the attenuated sliver receives a small amount of twist and is then wound on bobbins suitable for creeling at next process.

In this process drawn sliver is input and fine roving is output. The roving is feed into ring frame for yarn production. It is noted that, simplex is essential for the production of cotton yarn in case of ring spinning by ring spinning system.

Other Names of Simplex Machine

- Fly frame.

- Roving frame.

- Speed frame.

Objects or Functions of Speed Frame

- Attenuation of drawn sliver to form roving of required count by drafting.

- Insert small amount of twist to give required strength to roving.

- Wind the twisted roving onto the bobbin.

- Build the roving in full length of bobbin in such a form which will facilate handling, transfer and feeding to ring farme.

The main Operations or Functions of Simplex Machine

Various types of objectives are achieved by simplex machine. Followings are the main functions of simplex machine:

- Creeling: Creeling is the first objective of simplex frame arrangement. By the creeling, small amount of draft is applied to the drawn sliver.

- Drafting: Attenuation of drawn sliver to produce required amount of roving by drafting. Thick drawn sliver is converted into thin roving by drafting system.

- Twisting: Small amount of twist is inserted in the drafted stand of fibres by the twisting. The amount of twist is very low.

- Building: Build the roving on to bobbin such a form which will facilate unwinding, handling and transfer to the next process.

- Winding: Produced or twisted roving is wound on the bobbin by the winding process. This bobbin is feed to the ring frame and this bobbin accelerates the next process. So, it is important.

- Doffing: It is the optional function of speed frame. Doffing could be done manually or automatically.

So, simplex frame plays an important role in the spinning process. Various types of yarn faults could be appear for the wrong drafting or twisting. For this reason, the operator should be careful during the process.

Nice article…………….thanks PTECian

Thanks for this article.

Your blog provided us with valuable information to work with. Thanks a lot for sharing.

Discount coupon

thanks lot

Good input

Hello there! This is my first comment here, so I just wanted to give a quick shout out and say I genuinely enjoy reading your articles. Can you recommend any other blogs/websites/forums that deal with the same subjects? Thanks.