Common Sewing Machine Problems and How to Fix Them

Last updated on December 25th, 2025 at 10:44 am

Introduction

A sewing machine is an essential tool for anyone who enjoys sewing or creating their own clothing. However, just like any other mechanical device, they run the risk of breaking down and becoming useless.

You’ll be glad you spent the effort in the long run to figure out the most typical issues with sewing machines and how to fix them. We’ll go over the most common problems and provide you step-by-step guidance on how to fix your sewing machine.

Putting together a nest from scraps of thread

Instead of sewing, the thread loops or knots under the fabric, creating a tangled mess.

Solution:

It’s crucial to use the take-up lever and tension plates properly when threading a sewing machine.

Focus on the pointer. First, make sure the bobbin is threaded and spinning. No knots should form in the bobbin thread, making it easy to wind.

Thread bunching occurs when the tension is off, so make sure you readjust it. Tweak the top thread tension as suggested by the machine’s instructions.

Unfinished sewing

The machine creates holes because it sews unevenly or skips stitches.

Solution:

Put in a new gauge. A needle that is too dull or crooked could be the problem. Before you start stitching with the new needle, check to see if it is appropriate for the fabric you are using.

Check that the needle size is suitable for the thickness of the fabric. Needles should be progressively larger as cloth thickness increases.

Make sure the needle is pointed in the right direction and rethread the machine if necessary.

Razor-sharp needles

When I try to stitch, the needle keeps breaking.

Solution:

The right needle must be inserted. If you’re sewing, be sure your needle is appropriate for the fabric. Not all textiles can be sewn with a ballpoint or universal needle.

See to it that the needle is inserted correctly and is pointing in the right direction.

You can adjust the stitch length to suit your needs. If the stitches are excessively tight or the fabric is too thick, the needle may break. It is possible to achieve better outcomes by decreasing the stitch length.

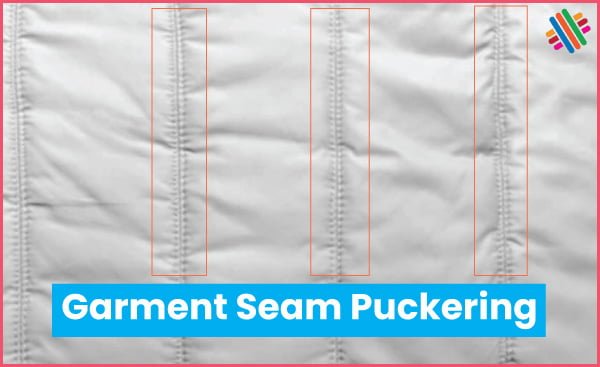

Fabric that puckers or has uneven stitching

If the fabric puckers or the stitches appear uneven, that’s a sign.

Solution:

Check out how clean the machine is. Accumulation of dust and lint in the bobbin case and feed dogs can lead to uneven stitches. You should clean and oil your sewing machine as directed by the manual.

Make it more succinct. Stitching that is not evenly tensioned might look sloppy. You can try out several tensions to find the one that best suits your fabric.

A leveller should be used. Using a stabiliser prevents puckering in even the thinnest fabrics.

At the top, you can see the bobbin thread

The thread from the bobbin is exposed and easy to see.

Solution:

Check that the bobbin is threaded correctly. Wind the thread in the correct direction and place it in the bobbin case to complete the bobbin assembly.

Some sewing machines let you adjust the bobbin tension for a looser or tighter stitch. Check to see if you can tweak the guidelines to make this work.

The procedure generates a lot of background noise

The symptom is that the sewing machine makes strange or loud noises when in use.

Solution:

Clean and lubricate the machine. Extra noise is produced by increased friction when not enough oil is present. Check the instruction handbook to find out where the oil fill-up is.

Find the source of the vibrations by checking the various parts for loose screws or other components. If they are too loose, tighten them.

Fabric feeding Issues

You’re having trouble getting the fabric to cooperate with the sewing machine.

Solution:

Get rid of the dog food. If lint and other debris build up, the feed dogs could get trapped. A brush and some compressed air should do the trick.

The height of the feed dogs needs to be checked. If the feed dogs are too low or too high, the cloth may not be fed properly. To learn how to change the height of the feed dog, consult the user handbook.

There is a problem with the bobbin or the needle

Symptom: It’s hard to get the thread or needle out of the machine.

Solution:

Turn off the machine. Always turn the machine off before attempting to remove a jam to avoid damage.

Take off the bobbin case or the needle plate very carefully. Follow your equipment’s instructions to get to the trapped area without risking injury. Don’t rush through removing obstacles and putting everything back together again.

Conclusion

Knowing how to fix common problems with your sewing machine will make your projects move more quickly and easily. If you keep up with regular maintenance and follow the manufacturer’s guidelines, you may extend the life of your sewing machine and reduce the frequency with which these problems arise. Use your needle and thread with delight.

Frequently Asked Questions (FAQ)

What is Thread breaking or bunching up?

Thread breaking or bunching occurs when there is improper threading by using the wrong thread or needle.

Why is the sewing machine not turning on?

Check if the power cord is connected correctly, the power switch is on, and if there are any blown fuses or tripped circuit breakers.

What is the most common cause of stitching problems?

The most common cause of stitching problems in a sewing machine is incorrect thread tension.

What causes stitch missing?

The main causes of missing stitches are damaged needle, incorrect needle size, incorrect needle type, incorrect threading, improper bobbin winding or installation, etc.

Why is my machine cutting thread?

When the machine is cutting the thread unexpectedly during sewing, there could be a few possible reasons for this issue. The reasons may be a damaged needle, incorrect needle size, low thread quality, incorrect thread tension, needle hitting, abnormal sewing speed, bobbin issues, etc.

About the Author

Ashley Brown is a passionate author and sewing enthusiast. With expertise in sewing machines, she combines her love for creativity and technical knowledge to inspire readers with her practical tips and innovative ideas for mastering the art of sewing.