An Overview of Straight Knife Cutting Machine

Last updated on August 25th, 2023 at 08:33 pm

Straight Knife

Most cutting room which cut garments in bulk, but not in sufficient bulk to justify the purchase of computer controlled cutters, makes use of straight knives.

Requirements of cutting:

- Precision in cut.

- Clean edge.

- Infused edge.

- Consistency in cutting.

- Support.

Features

- Cutting knife is straight in shape.

- Blade length – 10”-13” (10-33),

- Blade width – 1.5 cm,

- Blade thickness – .5 mm,

- Knife is driven by electric power.

- Grinding wheel is present to sharp the knife during cutting.

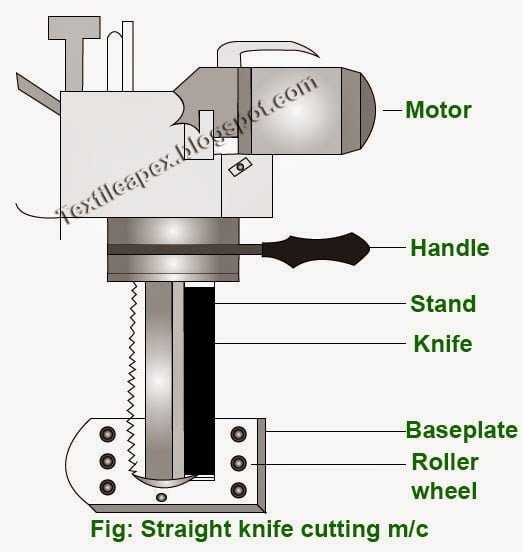

- The machines consist of base plate, electric motor, handle, knife, knife guard, stand, roller wheel.

- Base plate usually on roller wheel.

- Handle for the cutter to direct the blade.

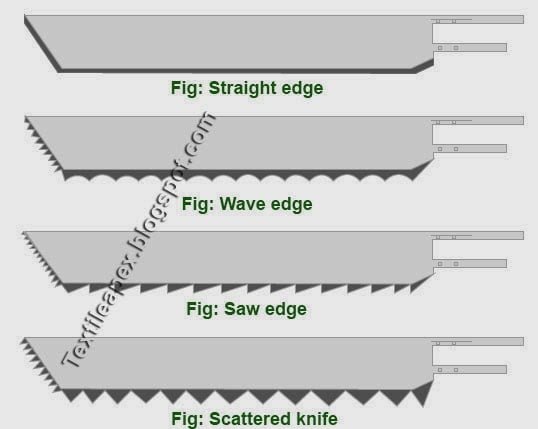

- Blade edge: Straight edge, Weave edge, saw edge, scattered edge, but straight edge is mostly used.

- Most commonly used in garments industry in Bangladesh (99% used).

M/C Description

The elements of a straight knife consists of –

- A base plate – Usually in rollers for easy movement.

- An electric motor.

- Handle – for the cutter to direct the blade.

- Knife (Reciprocating motion).

- Knife guard.

- Grinding wheel – used to sharp the knife during cutting.

- Stand.

- Roller wheel – to move the machine over cutting table easily.

It is

- Suitable for mass trimming cotton, woolen, linen leather and chemical fibre goods etc.

- Neat cutting, small curvature radius curvilinear cutting.

- Low noise, stable running, easy to operate and high efficiency.

- Incorporated with an auto knife grinding device, easier to operate.

Working Principle

Two kind of power are required to operate a straight knife.

- Motor power drives the reciprocating blade.

- Operator power drives the knife through the lay.

The motor power needed is determined by –

- Height of the lay.

- The construction of the fabric.

- The curvature of the line being cut.

- The stroke of the blade.

The greater the power of the motor the heavier will be the machine. The taller stand, the thicker its cross-section and the greater its width, adding resistance to the forward movement on a curve. The greater the blade movement the faster the blade cuts the fabric and the more rapidly and easily the operator can push the machine. Operator effort is affected by the weight of the motor, the shape of the stand, handle height, stroke, sharpness of blade and the effect of the base plate rollers on the table surface.

Advantages

- Comparatively cheap.

- Can be easily transferred from one place to another place.

- Round corners can be cut more precisely than even round knife.

- Production speed is very good as up to 10 heights can be cut at a time.

- Garment components can directly be separated from fabric lays.

- Fabric can be cut from any angle.

- Most commonly used in garments industries of Bangladesh (99%).

Disadvantages

- Sometimes deflecting may occur due to the weight of the motor.

- Knife deflection is high in risk, when any height is too high.

- Sometimes accident may happen.

Precaution to Avoid Blade Deflection

- Reducing lay height.

- The weight of the motor should be light.

- The operator should be skilled and conscious.

You may also like: Working Instruction of Garment Cutting Section

Kating map video den

Please contact me. I need some details on cutting blade. amrithraj.kg@gmail.com

It’s always so sweet and also full of a lot of fun for me personally and my office colleagues to search your blog a minimum of thrice in a week to see the new guidance you have got.