The Needle: The Heart of Knitting

Last updated on August 21st, 2023 at 11:42 am

In all knitting machines, the main element for the intermeshing of loops is ‘the needle.’ Earlier straight pins were used in hand-knitting to kink the yarn to form a circle and intermesh the new loop through the old one. When the machine was developed in 1589 by William Lee, ‘a spring beard needle’ was used. Later on, in 1847, ‘a latch needle’ was created, and in the 20th century, ‘a compound needle’ was developed. However, the principle of knitting remained unaltered.

The knitted fabric’s quality depends mainly on the effectiveness and accuracy of the loop-forming element, such as a needle. Minor variations in needle manufacture can lead to the irregular fabric. The surface of it should be highly polished, allowing the yarn and the loop to slide freely. It should have high strength and toughness to give durability. It should also perform several million knitting actions without fault. There are mainly three types of needles used:

- The spring beards

- The latch

- The compound needle

The Spring Beard Needle

This is most commonly used on a tricot warp knitting machine. The main parts are:

The head

The hooked portion of the stem of the needle to draw the new yarn, form a loop and intermesh through the old loop.

The Beard

The continuation of the hooked portion which has a good springiness and the shape of a beard on a chain.

The Eye

A groove cut in the stem to receive the pointed tip of the beard when it is pressed in by the pressure so that the new loop is entrapped.

The Stem

Around which the loop is formed and fabric is heald with the last loop on it.

The butt

Is bent for location in the machine or is cast with other needles in a metal lead.

The beard needle was the needle used in the first knitting machine known as the ‘stoking frame.’ The invention of the beard needle in 1589 is attributed to Rev William Lee. It is a single unit but external assistance needed to close the beard. It does not require a latch and riveting of the latch to the needle. It is therefore finer in its cross-section and more needles in a unit space can, therefore, be accommodated. Hence a finer gauge of the machine can be achieved. (The term ‘gauge’ is the designation of the ‘number of needles per inch,’ in the case of weft knitting and tricot warp knitting and it is the designation of ‘needles per two inches’ of the needle bed in the case of Rasel warp knitting).

You may also like: What is Knit Fabric: Definition and Meaning

In the case of bearded needle machines, 50 needles to an inch was a common gauge over 100 years ago but now gauges up to 60 needles to an inch are available. The beard needles are less expensive than the latch needles. However, they require additional help to close the beard, which is usually provided by pressure. To that extent, motion to the pressure is an additional expense for the beard needle knitting machine. It is claimed that the beard needle produces superior knitted stitches when compared to those of a latch needle. Most of the warp knitting machines like tricot, Simplex and Milanese machines use the beard needle.

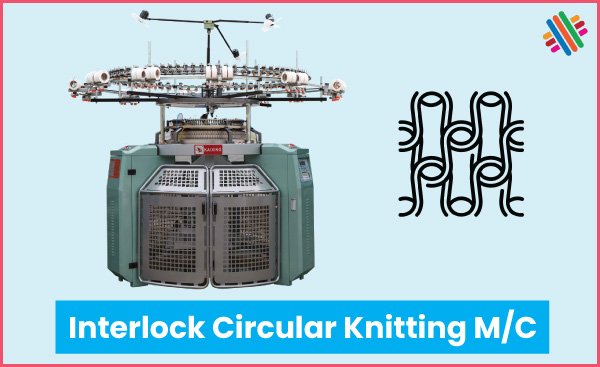

The Latch Needle

It consists of a hooked portion at the top, with a latch or spoon riveted at a certain distance from the head of the needle. The latch needle forms a stitch with a simple up and down movement. They are given individual movements, sliding in grooves, called the ‘tricks’ of the cylinder. The latch can swing freely. The stem or shank is a straight portion of the needle with a protruding butt, some distance from the end of the needle. The reciprocating movement to the needle in the vertical direction is given through this butt part of the needle. Latch needles are mainly used in circular weft knitting machines for single knit and double knit fabrics. They are also used for the purl fabrics and in V-bed and flatbed machines and on Raschel warp-knitting machines.

These needles are self-acting, in that, they require only a previous loop on the stem and do not require any outside agency to close the hook. The swinging latch has a cup at the end to fit the hook in the groove when the latch is closed. The latch is riveted to the stem. Because of these facts, the total thickness or the space occupied by a latch needle cannot be reduced beyond the capacity of the mechanical means of manufacturing. Hence these needles are coarser in dimensions than the spring beard needles, with the result that the machines with finer gauges use spring beard needles. The latch needles are expensive because of the assembly of the needle and latch.

Awesome……

Thanks for this essential article….

Hey, would you mind if I share your blog with my twitter group? There’s a lot of folks that I think would enjoy your content. Please let me know. Thank you.