Tappet Shedding: Definition, Types, Position and Construction

Last updated on August 21st, 2023 at 11:09 am

Definition of Tappet Shedding

Tappet, Cam is the names given indiscriminately to those irregular pieces of mechanism. A rotary motion is given to produce reciprocating motion in the rod and levers for shedding.

Types Tappet Shedding

We can divide it into the following two types:

Positive

These give both upward and downward movements to healds without the aid of any additional mechanism. But pullers, stocks and bowls are based on compensating principles.

Lifting and lowering → Mechanically. Which are-

- Wood crofts section tappet.

- The oscillation tappet.

- Neutrals chain tappet.

- Scroll tappet.

Negative

These require the addition of pullers, stocks, and bowls, springs, or dead weights to reserve either pulls the head down or lifts it. Which are-

- Ordinary plain tappet.

- Jamieson’s tappet.

- The barrel tappet.

Position of Fixing Shedding Tappet

- Over or under the centre of the heald shaft.

- Over or under one end of the heald shaft.

- Outside of the loom frame.

Over or under the centre of heald shaft: When the device is placed over the centre of heald shafts, then the oil, grease etc. applied to trade bowl for antifriction property may fall on the fabric and contaminate it when placed under the heald shafts, some difficulties may arise while cleaning.

Over or under one end of the heald shafts: When the device is placed over or under one end of the heald shaft, pressure is applied at any one side of the heald shaft. Hence connecting cards should be used on two sides.

Outside of the loom frame: In this system, it is easy to clear the tappets and to apply grease, oil to trade bowl, and easy maintenance can be done. But it requires more space.

Construction of Tappet for Plain Weave

To design a shedding tappet for plain weave, the following particulars have been taken into consideration-

- Lift if tappet-4.”

- Distance from the center of the driving shaft to the nearest point of contact with the trade bowl-2.”

- Dwell of tappet one-third of pick.

- Diameter of the trade bawl-2.”

At a radius of 2 inches, the circle – A. This circle represents the distance from the centre of the driving shaft to the nearest contact point with the tradle bowl. For plain weave tappet, the bottom shaft is used as a driving shaft. At a radius of 3 inches, the circle – B and one inch are added for the radius of the tradle.

At a radius of 7 inches, the circle –C. Four-inch is added for the lift of tappet. The circle represents the centre of the tradle bowl when the inner circle is acting upon the bowl. The circle ‘C’ represents the centre of the bowl when pressed down by the device. Divide each half circle into three equal parts by lines FK and GH. Divide FH and GK into six equal parts and divide the space between the circles B and C into six unequal parts. To find out the six unequal parts, describe a semi-circle L between B and C. Now divide its circumference into six equal parts and then draw a perpendicular line from them on the line GH. This gives six unequal divisions on the lift to obtain the desired eccentric shape of the tappet. From the corner of these unequal spaces and with the tradle bowl describes circles representing the tradle bowl’s position at different parts or its movement. Now draw the curved lines touching the extremities of the tradle bowl. This gives the outline of the plain tappet.

Conditions of Good Shedding

- A shed should be as small as the nature of the work to be done.

- Healds should be placed at right angles with the warp threads.

- Exact vertical movement of the heald shafts is required.

- Perfect levelling of the headl shaft.

- The heald shafts must begin to move slowly.

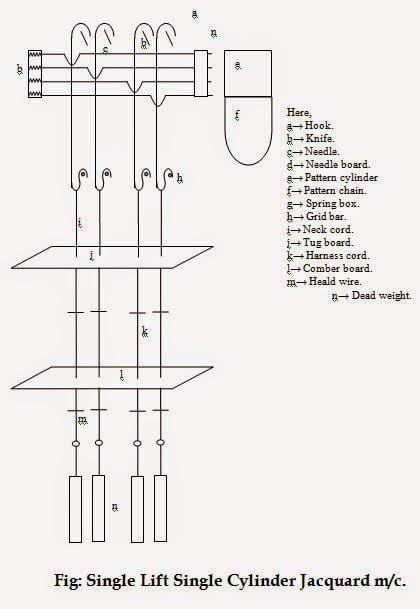

You may also like: Harness Mounting System of Jacquard Loom

It is quite different from others……Nice

please answer me why tappet mechanism didnot use more than 12 healdframe

its very helpful…