Working Instruction of Garment Cutting Section

Last updated on July 8th, 2023 at 11:36 am

The garment cutting section is the most crucial in garment industries. In this section, fabrics are cut according to the marker dimension. There are two types of fabric-cutting methods. One is manual, and the other is computerized. Cut fabrics are sorted according to the sizes and then numbered. Numbering is done to avoid shade variation of the fabrics. So, during numbering, extra care must be taken.

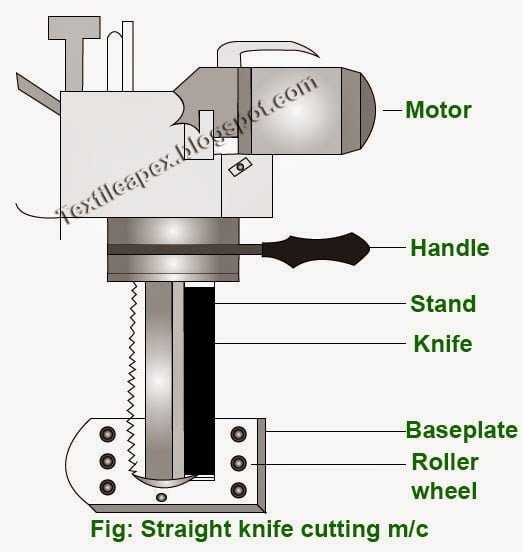

The bond knife is used to cut smaller parts of garments. The straight knife is mainly used in garment industries to cut long portions. It can also cut the curve portions of garments.

As the garment cutting section plays an important role, the workers and engineers should maintain some work instructions for better output.

Working Instructions in Garment Cutting Department

- Before bringing the fabric into the cutting section, the fabric is matched with approved fabric by the buyer (Generally, GSM and Shade variation is measured).

- If the color, shrinkage, spirality, fabric dia, width, and GSM are matched 100%, then the fabric is received in storage.

- Then the fabric is inspected by 4 point system, and the defects are recorded.

- The OK fabric should be kept in relaxation for 24-72 hours.

- Then the fabric is laid on the table very carefully without looseness or tension free.

- Fabric lay height must be in the range of 2.5 – 3 inches, and the length is between 7 yds.

- The black and white fabric cannot be laid on the table.

- Before cutting the fabric, the marker, and pattern must be checked.

- In pattern length, chest, waist, bottom, sleeve length, sleeve open, and its style must be checked, and the operator must wear metal hand gloves.

- After cutting, the cut panel must be bundled, and for checking, it should be taken to the quality table.

- 100% record must be collected.

thanx!