Last updated on August 23rd, 2023 at 12:15 am

Definition of Textile Dyeing

The dyeing process is aimed at giving woven or knitted fabric its intended color, crucial to its ultimate use. The process can be carried out at different stages of fibre processing, i.e. in different forms: staple, yarn, fabric (rope or open-width), and piece. When the process is carried out during the first processing stages, for example on staple fibres, a better colorfastness can be achieved; bulk dyeing refers to the system used to dye a staple fibre before it is spun, this process is carried out in perforated baskets and although there may be areas where the dye does not penetrate completely, in subsequent spinning operation, these areas are mixed with the thoroughly dyed fibre, thus ensuring an overall even color.

Yarn dyeing is carried out after the fibre has been spun into yarn. It is preferred for manufacturing jacquard or striped fabrics; this method grants a good color fastness since the dye penetrates the fibres and reaches the yarn core. Skeins are dyed in hanks, spools are dyed in autoclaves and warp yarns are dyed in perforated beams loaded in autoclaves.

Piece dyeing is carried out on several types of machines and the material can be open-width or rope dyed. A good result strictly depends on different parameters and conditions that can be evaluated immediately (such as good consistency of the dye and repeatability) or which require specific fastness evaluation (manufacturing, use, dry or wet processing) that can be controlled only by means of subsequent laboratory tests.

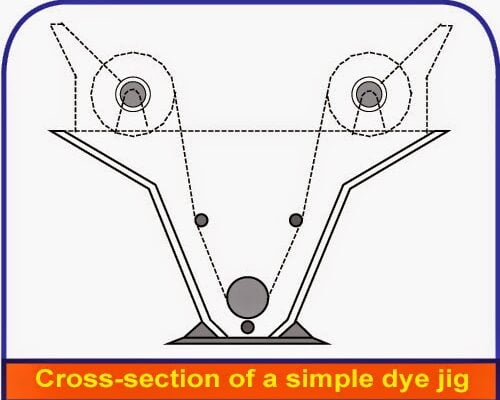

The machines used are chosen accordingly to the material to be processed. The crucial requisites are the following:

- Protection of the substrate

- The repetitiveness of the results

- The cheapness of the process (depending on the processing time, machine automation degree, liquor ratio, cost of the products used and wastewater purification).

Textile materials are dyed in aqueous solutions or dispersion of dyestuffs, together with dye bath additives such as salt, alkali, acids and other auxiliary chemicals. The dissolved or dispersed dyestuff must first, be absorbed onto the fibre surface and then diffuse into its interior where finally it must be fixed.

To carry out a dyeing process it is necessary to:

- Dissolve or disperse the dye in a water bath (with manual, semiautomatic color kitchens according to specific preset rules).

- Feed the dye solution in the machine after suitable filtering (automatic color kitchen, supplementary vats, pumps and filters).

- Transfer the dye from the liquor to the fibre (process and machine).

- Distribute the dye homogeneously on the fibre (process and machine).

- Let the dye penetrate the fibre structure and fix it (time and temperature).

- Wash or rinse the material to remove the dye on the surface or the unfixed dyeing liquor.

There are two different methods to transfer the dye from the liquor to the fibre:

Exhaust Dyeing (discontinuous system)

The dye is dissolved or dispersed in the dyeing liquor. The material is immersed in the dyeing liquor and is removed only when the dye has mostly transferred onto the textile to be dyed, distributed homogeneously, well penetrated into the fibre and fixed. At the end of the process, the material is washed or rinsed to remove the unfixed dye.

Pad Dyeing (continuous or semi-continuous systems)

This process is carried out using mechanical means (pad-batch wetting). The dyeing liquor is distributed homogeneously onto the fabric (i.e. also the dye is distributed homogeneously). In a second stage, the dye penetrates into the fabric and is then fixed. At the end of the process, the material is washed.

Some operations must be carried out for both exhaust and pad dyeing

- Dissolve or disperse the dye in water and filter.

- Achieve a homogeneous contact between the dyeing liquor and the fibre.

- Make the dye penetrate into the fibre.

- Fix the dye in the core of the fibre.

- Final washing

![Continuous Dyeing Method [Thermosol]](https://textileapex.com/wp-content/uploads/2015/02/thermosol-dyeing-machine.jpg)

This is a basic term….We should know it.

Nice article….

Thanks brother.

Hello, I read your blog occasionally, and I own a similar one, and I was just wondering if you get a lot of spam remarks? If so how do you stop it, any plugin or anything you can advise? I get so much lately it’s driving me insane, so any assistance is very much appreciated.