Observation of AOO2D Automatic Bale Plücker

Last updated on September 23rd, 2023 at 10:35 am

Application

This machine being in the initial stage treatment of raw materials in the blow rooms is suitable for cotton, cotton type man-made fibres. The pluck-beater travels around and lowers intermittently to pluck the fibres in succession. Drawn by fan, these fibres are delivered to the nest machine through the conveying for treatment.

Main Specification

- Dia. of out round frame – 4760 mm.

- Inner round frame (rotary type) – 1300 mm dia.

- Carriage frame – Length: 2640 mm, Width: 800 mm, Height: 1425 mm.

- Speed of the carriage – 1.7~2.3 rpm.

- Pluck beater – Dia: 385 mm, Speed: 740rpm, Blade: Zigzag type.

- Blade arrangement – First group: 9 teeth, Second group: 12 teeth, Third group: 15 teeth.

- Working length – 1618 mm.

- Position of the beater blades end above the ground – max~1110 mm and min~ 30mm.

- Stepwise lowering of beater – 3-6 mm each time (Adjustable).

Description

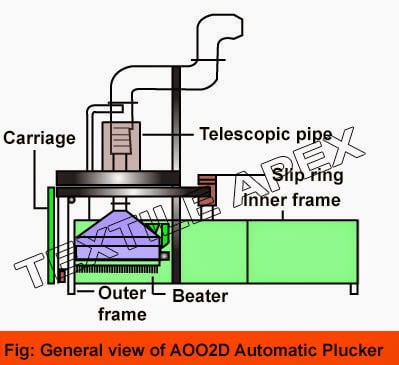

This machine is composed of inner round frame, carriage frame, beater frame, beater, centrifugal switch, telescopic pipe, outer round frame, slip ring and rail.

The carriage is connected to the outer frame and supported at the center on a central shaft. With two rollers wheels at the bottom of the carriages outer frame, the carriage can revolve clock wise on the circular rail.

The plucking beater is supported by four screw-rods, among which the two located at the outer side are fixed to the beater frame, and their respective, threaded nuts can rotate. While the inner two screw rods can rotate, & their respective threaded nuts are secured to the beater frame. When two threaded nuts of the out two screw rods & the inner two screw rods rotate synchronously, the beater and the beater frame are driven to 90 up & down. There is a sleeve barrel in which each screw rods to prevent the beater from cotton enclosing.

The beater consists of zigzag blade, spacer, end plate & beater shaft. With bolts and nuts, zigzag blades are fixed to flange. For each spacer, there are three groups of teeth of zigzag blades – 9 teeth of inside, 12 teeth of middle, & 15 teeth of outside. The blade can be exchanged.

The centrifugal switch that is speed relay is fixed to the beater frame. It is driven by beaters belt pulley.

The inner frame travels around together with the carriage. There are three wheels at the bottom of the inner frame. The seal leather at the lower end of the inner frame is designed for preventing fibres from entering.

The out frame is mounted on the ground. Cotton bales are put within the out frame. There are two doors on the out frame.

The slip ring assembly consists of bearing, sleeve, connect limit switch or carriage lowering & adjustable feeler. The bottom seat & sleeve have to be fixed to avoid sleeve & inner ring travelling along with the outer ring.

Three motors are provided for this m/c for operating the beater travel, lifting & lowering of the beater & carriage separately.

Machine Adjustment

- The blade extension from grid can be adjusted to get the required dimension by adjusting the thickness of the pads.

- When the carriage travels one round, the plucking beater lowers once. The lowering distance can be regulated by adjusting the touching time of the limit switch in slip ring assembly and the feeler.

Precautions

- Firstly the condenser fan of the next machine in the B/R line (here the multi-mixer) should be started. Then the beater of the plucker m/c should be started.

- After switching on the m/c, start the beater first, then the carriage.

- When the carriage travels one round, it should be observed how much the beater lowers, and then it should be adjusted properly.

- The photoelectric cell in the hopper of the next machine controls the carriages running. It should be observed whether the control system is good or not, & then adjustment of lowering of carriages should be done according to its evolutional rate.

You may also like: Blow Room: Definition, Objects and Process Layout