Honeycomb Weave Fabric Structure: An Overview

Last updated on May 2nd, 2024 at 11:23 pm

The term is applied to weaves which resemble honeycomb cells. The cellular formations appear square in the cloth. They are formed by some ends and picks interlacing tighter than others and therefore developing a higher tension. Usually, single cloths are made by progressively lengthening and shortening both warp and weft floats to form ridges and hollows on a square pattern, to give a cellular appearance.

There are two types of honeycomb weaves, such as – Ordinary honeycomb and Brighton honeycomb.

Ordinary Honeycomb

Main Features

The main features of ordinary honeycomb are as follows –

- Surface of produced fabric is rough.

- Similar appearance or effect formed in both sides of the fabric.

- In repeat size, ends and picks are equal or unequal.

- Repeat size is multiple of two.

- Smallest repeat size is 6 X 4.

- One cell in each repeat.

- V – draft or pointed draft is found.

- Simple construction.

Construction Principle

The stages of constructing an ordinary honeycomb weave are as follows –

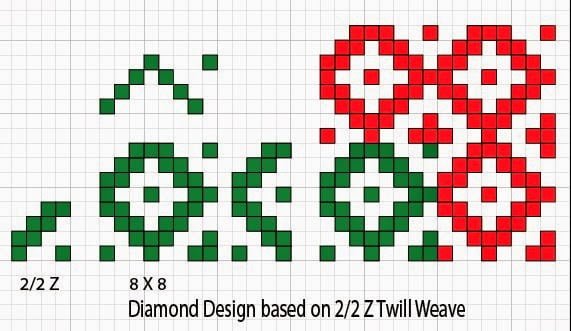

- Construct a 1/a Z twill starting in the bottom left-hand corner, then a similar one running in the opposite direction and starting one square down from the top left-hand corner, so that there will be a clean intersection of the twill lines, as at first stage.

- In one of the two diamonds produced, leave a row of stitching points and then lift the remainder of the diamond solid. This is the final weave.

The following figures show the weave plan with drafting and lifting plan of different equal and unequal repeat sizes of ordinary honey comb weaves –

End Uses

This weaves is particularly suitable for hand towels, glass cloths, dispensed roller towels and bath mats, where moisture absorption properties are particularly desired, but in similar coarse cotton qualities it is also used for quilts and soft furnishings, and in finer qualities for shirts and brocades. In conjunction with the newer textured yarns, it is produced in very coarse qualities for cellular blankets.

You may like also: Diamond Weave Design

Brighton Honeycomb

Main Features

Brighton honeycomb is a complex structure. The main features of Brighton honeycomb are as follows –

- More honeycomb cells of varying size are produced in this weave.

- The fabric surface is also rough as ordinary honeycomb.

- When making the weave, the number of threads per repeat should always be a multiple of (i.e. 12 ends X 12 picks), whilst the longest float should always be one less than half the number of threads in the repeat (i.e. 12/2 – 1 = 5).

- Both sides of the fabric look the same like as ordinary honeycomb.

- Straight drafting system is used to produce this Brighton honeycomb weave.

Construction Principle

The construction more complicated than the ordinary honeycomb, is illustrated by figures below, with the following stages –

- Construct a 1/a Z twill, starting in the bottom left-hand corner, and then construct a 1/a S twill, starting with the first warp lifts in the squares to the right and below the square in the top left-hand corner, and indicate the points on the double row of binding which are immediately adjacent to those of intersection that will allow extensive floats in the weft direction, as illustrated in the first stage;

- Using the points indicated in first stage as the extreme lift of the longest float, lift the remaining adjacent ends, as in second stage;

- Each of these warp floats now form the centre float of a diamond which can be completed. This is the final weave.

The draft of the brighton honeycomb is straight, this producing a lifting plan which is identical with the design; therefore, there is no saving of heald-shafts as is the case with the pointed or V-draft of the ordinary honey comb.

End Uses

Although the weave is not as popular as the ordinary honeycomb, it is used in similar qualities for more decorative end uses such as quilts and brocades and, in some cases, hand towels and glass cloths. It is also suitable for crockery towels.

Reference

Understanding textiles for a merchandiser by Engr. Shah Alimuzzaman Belal.

Nice article.

Thanks Abu for sharing such an interesting article. Just keep sharing.

Can anyone tell me what is the key different between those two types ?

Nice illustration through images…Thanks

Those guidelines additionally worked to become a good way to recognize that other people online have the identical fervor like mine to grasp great deal more around this condition.