An Overview of Anti Microbial Finish

Last updated on September 24th, 2023 at 11:21 am

Introduction

The growth of microorganisms on textile can lead to functional, hygienic, and aesthetic difficulties (for example staining). The most trouble-causing organisms are fungi and bacteria. Under very moist condition, algae, can also grow on textiles but are troublesome only because they act as nutrient sources for fungi and bacteria. Fungi cause multiple problems to textile including discoloration, colored stains, and fibre damage. Bacteria are not as damaging to fibres, but can produce some fibre damage, unpleasant odors and a slick, slimy feel. Often fungi and bacteria are both present on the fabric in a symbiotic relationship.

Substances add to the fibres, such as lubricants, anti-stats, and natural-based auxiliaries (for example size, thickener and hand modifiers) and dirt provide a food source for microorganisms. Synthetic fibres are not totally immune to microorganisms, for example polyurethane fibres and coatings can be damaged. Of course, because of evolution, natural fibres are more easily attacked. Wool is more likely to suffer bacterial attack than cotton, and cotton is more likely than wool to be attacked by fungi.

The use of antimicrobial finishes to prevent unpleasant odors on intimate apparel, underwear, socks, and athletic wear is an important market need. The odors are produce by the bacterial decomposition of sweat and other body fluids, and controlling bacterial growth by hygiene finishes reduces or eliminates the problem.

Ideal Condition for Bacteria Population

Temperature: 36 – 400 C.

Ph: 5 -9

The growth rate of microbes is very much rapid and will double in every 20 to 30 min under ideal condition. At this rate, one single bacteria cell can increase to 1,048,576 cells in just 7 hours.

Aims

- Protection of textile.

- Protection of textile user.

Application Areas

- Industrial fabrics those are exposed to weather (Screens, tents, tarpaulins, ropes).

- Home furnishing carpeting, shower curtains etc.

- Textiles for hospitals, nursing homes, schools, hotels, and crowded public areas.

- Textiles in museum.

- Sized fabrics those are to be stored or shipped under high temperature.

- Textiles left wet between processing steps.

Properties of an Effective Anti Microbial Finish

- Quick acting.

- The antimicrobial must kill or stop the growth of microbes.

- Fastness properties.

- Safe for manufacturers to apply and the consumer to wear.

- Minimal environment impact.

- Easy to apply.

- Compatible with other finishes.

- Selective operation.

Mechanisms of Anti Microbial Finishes

- Controlled release mechanism

The antimicrobial is slowly released from a reservoir either on the fabric surface or in the interior of the fabric.

- Leaching type antimicrobial.

- Effective against microbes on the fibre surface or in the surrounding environment.

- Bound antimicrobial.

Chemistry of Anti Microbial Finishes

- Antimicrobial for controlled release:

- Copper naphthenate.

- Copper – 8 – quinolinate – Formerly used.

- Organo mercury compounds – Now strictly regulated for their toxicity

Other materials that still have limited used in specialized areas

- Tributy tinoxide.

- Dichlorophene.

- Triclosar.

Extensively used in:

- Mouthwash.

- Toothpaste.

- Liquid hand wash.

- Deodorant.

- Bound antimicrobials:

- Octadecyl aminodimethyl trimethoxy silypropyl ammonium chloride.

- Polyhexamethylene biguanide.

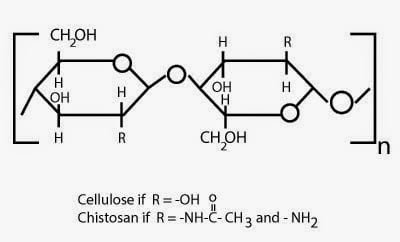

Chistosan as Natural Antimicrobial

Modified bio-polymer manufactured from inexpensive natural waste.

Chistosan can be applied by micro encapsulation or by reactive bonding to cellulose by cross-linking of chistosan.

Advantages of Chistosan

- Absorbent

- Moisture control.

- Non-allergic

- Non-toxic

- Bio degradable

You may also like: An Overview of Water Resistant and Wind Resistant Clothing