Tough Cotton: Durable Technology for Cotton that Gives Higher Performance

Last updated on January 7th, 2026 at 09:04 pm

People always want to purchase tough, durable, long-lasting clothing, especially for children and athletes’ apparel, for using sustainable, long-lasting purposes. As usual, durability plays a crucial role in the decisions of purchasing clothing. Today tough cotton came with the solution of durable technology. In this context, we are going to learn about Tough Cotton and its durable technology.

Cotton is always known for its durability. Even it can withstand the most demanding challenges, like falling on the ground, climbing the trail, and dominating that sales pitch. But it’s not enough for the children, athletes, and military activity. Besides daily uses, home laundering weakens the fabric, makes fabrics abraded, causes cotton fibres to rise to the surface, and makes it seem faded. That’s why tough cotton technology introduces cotton that provides superior performance to humanity.

What is Tough Cotton?

Tough Cotton Technology is a specially engineered finish to improve the wear and durable press (DP) of cotton garments. It solves the holes and breaks problems in the clothing. Besides, it increases clothes durability and superior abrasion and resistance to wrinkles.

So go ahead, and GET tough with your dress. You would not be afraid of a bit of tear and poor performance of regular cotton. Knit and woven fabrics could be treated with tough cotton technology. It offers enhanced strength and durability with a perfect combination of abrasion resistance and colourfastness. Here are some properties of it:

- Produce super durable and robust fabric.

- Improved tensile and tear strength.

- Superior abrasion resistance.

- Improves crease edge abrasion.

- Good hand and drape.

- Reduces Shrinkage.

- Improves wrinkle resistance.

- Helps Maintain Original Colour.

- Applicable on woven and knit as well as denim fabrics.

- Prolongs product life and sustains the lifetime of the garment.

How Does Tough Cotton Technology Work?

These two types of tough-cotton technology have been introduced to offer superior performance. They are as follows:

Tough cotton with Resin

A unique combination of resins and catalysts to form flexible bonds on the cotton has to achieve superior durable press properties. It is used to improve the fabric strength and prevent breakage.

Tough cotton without Resin

The technology comes with flexibility with resin and non-resin. Non-resin is used in tough cotton technology with a proprietary blend of softeners and crosslinking agents to achieve superior abrasion resistance. It boosts up durability and strength as well as improves fabric sewability.

Both formulas are applied in fabric or apparel. Besides, both forms could be combined with other performance finishes, like storm cotton technology. It may help to achieve the ultimate performance of the cotton garments.

Mainly the flexibility comes from both resin and non-resin. But without resin, methods are used versatilely in industry. Consequently, we should talk about this technology without resin.

Key Chemicals for tough cotton without Resin

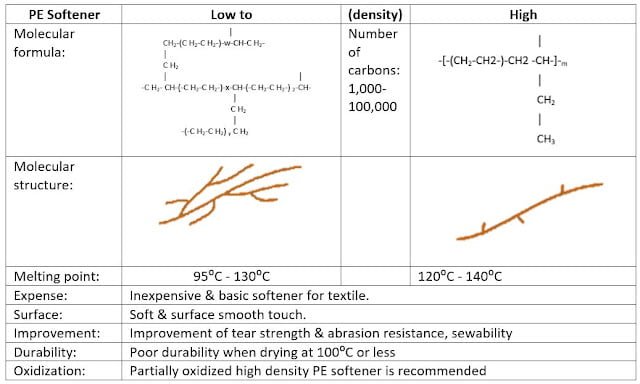

Polyethylene (PE) Softener

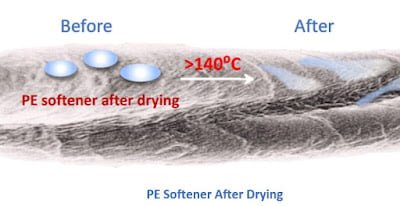

It’s used to improve abrasion resistance and tearing strength. It melts and sticks on cotton fibre and provides a soft and smooth surface touch.

Crosslinking Agent

Polyfunctional Blocked Isocyanate (PBI) is used to improve the durability of performance. PBI reacts with both cotton & PE softener and holds PE on cotton fibre firmly.

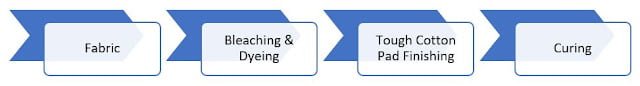

Finishing Flowchart of Tough Cotton without Resin

Application Flowchart

For Fabric

For Garments

For Denim

Process For Woven Fabrics

Preparation and Dyeing

- Prepare & dye the fabric using a standard process of the plant.

- The dyed fabric must be neutralized & rinsed, and check the fabric pH

- It must be utilised in the total alkalinity within fabric pH: 6.0‐7.0.

- After dyeing & neutralisation, the fabric needs to be dried without applying any finish, including softeners.

Finishing Formula

| Concentration | Chemicals |

|---|---|

| 1‐2 g/L | Wetting agent (anionic or non-ionic surfactant that a plant is currently using) |

| 50 g/L | High-Density Polyethylene Softener |

| 5 g/L | PBI (Crosslinking Agent) |

| 0‐50 g/L | Standard softener (optional) |

| 1 g/L | Acetic acid (56%) *May substitute citric acid, if desired. |

Finishing Process & Condition

Padding: 70-80% wet pick-up

Drying: 120‐130°C x 1‐2 minutes to 0-5% moisture

Curing: 150°C x 3 minutes

After curing, the fabric can be compacted, sanforised or processed with most any other mechanical finish.

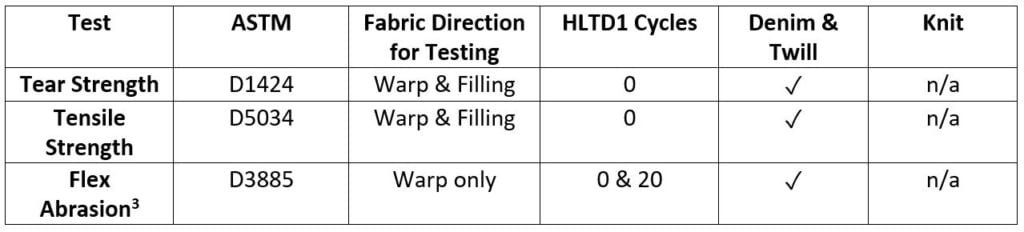

How to maintain performance testing?

Sampling Fabric Samples to be Collected:

Tough Cotton finish: 2 meters x full width

Control (before Tough Cotton finish): 2 meters x full width

Performance Testing (for Woven)

- Washing method: AATCC 135

- Normal/Cotton Sturdy 41±3℃-

- Tumble Dry: Cotton Sturdy

- Universal Wear Tester

Summary: technology applied without Resin

- Improvement of Abrasion Resistance and Tearing Strength.

- Highly durable in multiple laundries.

- Inexpensive and commercially available chemicals.

- Ease of application.

- Versatile application for knit/woven fabric or garment.

- Enhance the life of the garment.

Tough Cotton for Woven Fabric

Tough cotton technology brings an extra layer of protection to the woven fabric. Tough woven cotton offers improved abrasion resistance compared to untreated woven cotton, as seen in the picture. We can easily define the technology by following testing methods.

In the Stoll Flex Abrasion Test, warp ASTM D3885, tough cotton without resin 17290, the UNTREATED FABRIC scores only 2163. In 100% Cotton Twill, Tearing Strength, ASTM D1424, the untreated fabric scores 3.65, but the tough cotton non-resin scores 4.08.

Consequently, from lightweight twills to heavy-duty canvas, you never have to worry about that superior performance in snags, tears, and rips when climbing a mountain or doing a tough activity.

Tough Cotton for Knit Fabric

The treatment is used in knit fabric to achieve the benefits of resin finishing without using it. It helps to increase organic fabric treated with cellulase enzyme. Control finishes on knit fabric provide improved burst strength. Consequently, fabric burst strength is improved. Reducing shrinkage and smoothness are similar for this. Most importantly, less formaldehyde is used and released to nature with this finish.

Conclusion

A new durable press finish that makes woven and knit fabrics, as well as denim, stronger and longer than usual. The tough cotton treatment makes knits stronger and the fabric durable. No matter what you put them through. As a result, day by day the technology becomes popular between people and at the industry level. Clothing manufacturing factories and mills in Asia and North America have successfully adopted tough cotton technology. But in Mexico, they mass-adopt this technology.

Garments that are treated with this technology can withstand the toughest environments. Today the technology isn’t just for the kids. It is treated in adult clothing to provide more protection, such as in the toughest yoga poses. It keeps garments looking newer longer with improved abrasion resistance. Consequently, there is no need to replace your garments due to holes in the knees, elbows, or something like this. There is no doubt that tough cotton brings a durable technology for cotton that offers superior performance to humanity.

May I request that you elaborate on that? Your posts have been extremely helpful to me. Thank you!

very helpful article.