From Fiber to Yarn: The Carding Process in Yarn Manufacturing

Last updated on November 5th, 2023 at 12:34 am

Definition of Carding

Carding is a textile processing technique that involves cleaning, aligning, and blending fibres to create a continuous, uniform web or sliver of fibres. Carding primarily aims to prepare fibres for spinning into

yarn by separating and aligning the fibres to create a consistent strand that can be spun more efficiently and with better quality.

The carding process typically involves using a carding machine with a series of rollers or drums covered with fine wire teeth or carding cloth. The fibres are fed into the carding machine, which separates and combs them as they pass through the rollers. The carding machine may have multiple rollers that rotate at different speeds, called carding sections, to align further and blend the fibres.

As the fibres pass through the carding machine, impurities, such as dirt, grease, or vegetable matter, are removed, and the threads are aligned more parallelly. This process helps to create a consistent web or

sliver of fibres that can be further processed into yarn or other textile products.

Carding is an essential step in the textile manufacturing process, as it helps to improve the quality of the final yarn by creating a more even and consistent blend of fibres. Carded fibres are often used to produce yarns with a softer, loftier texture and can be blended with different types of fibres to create unique color patterns and textures in the yarn. Carding is commonly used in producing various yarns, including woollen yarns, cotton yarns, and blended yarns, and it is also used in non-woven textile

processes, such as felt making.

Definition of Carded Yarn

Carded yarn is made by carding fibres, typically natural fibres such as wool, cotton, or silk, or synthetic fibres such as acrylic or polyester. The carding process involves cleaning, aligning, and blending the

fibres to create a continuous strand of yarn.

Carded yarn is known for its lofty, soft, and fuzzy texture, as the carding process leaves the fibres more loosely aligned than other types of yarn, such as combed yarn. The carding process also helps blend different fibres, creating unique color patterns and textures in the yarn. Carded yarn is often used for hand spinning, hand knitting, and hand weaving, as well as in some commercial textile applications.

Carded yarns can come in a wide range of thicknesses, from fine lace-weight yarns to bulky yarns suitable for warm and cosy blankets or outerwear. The fibres used in carded yarns can also vary, allowing for various properties, such as warmth, softness, durability, and moisture-wicking. Carded yarns may be used in multiple textile applications, including clothing, accessories, home decor, etc.

Steps Involved in Carded Yarn Manufacturing

The carding process typically consists of several steps:

Fibre Preparation

The first step in carded yarn manufacturing is preparing the fibres. The fibres may be natural, such as wool, cotton, or silk, or synthetic, such as acrylic or polyester. The fibres are typically cleaned to remove any impurities, such as dirt, grease, or vegetable matter, and may be dyed at this stage if desired.

Carding

Once the fibres are prepared, they are fed into a carding machine. The carding machine has a series of rollers with fine wire teeth, known as carding rollers or carding drums, that separate, align, and blend the

fibres. The fibres are fed into the machine in small batches, and as they pass through the carding rollers, the fibres are combed and aligned in a parallel manner.

Blending

Different fibres can be blended during carding to create a yarn with specific properties, such as color, texture, or strength. For example, wool and silk fibres may be mixed to create a soft and lustrous yarn, or wool and cotton fibres may be combined to create a balance of warmth and breathability.

Sliver Formation

After passing through the carding rollers, the fibres are formed into a thin, continuous strand called a sliver. The sliver is usually several inches wide and is collected on a large spool or bobbin.

Drafting

The sliver is passed through a drafting system, which further aligns and stretches the fibres to create a thinner and more even strand. The drafting system typically consists of rollers rotating at different

speeds to pull the sliver apart and thin it out.

Twist Insertion

Once the sliver has been drafted to the desired thickness, it is fed into a spinning frame or spindle, where a twist is inserted to create the final yarn. The twisting helps to hold the fibres together and gives the yarn strength and stability. The amount of twist and the thickness of the yarn can be controlled by adjusting the tension and speed of the spinning frame.

Plying (optional)

Multiple strands of carded yarn can be plied together to create a thicker, stronger yarn. Plying involves twisting two or more strands of yarn together in the opposite direction of the original twist to create a

balanced yarn with improved durability.

Finishing

Finally, the carded yarn may undergo additional processing steps, such as steaming, setting the twist, and trimming, to give it its final appearance and properties.

After the finishing steps, the carded yarn is wound onto spools or skeins, labelled, and prepared for sale or further processing into finished textile products. The specific process and machinery used for carded

yarn manufacturing may vary depending on the type of fibre being processed, the desired characteristics of the yarn, and the production scale. Still, these are the general steps involved in carded yarn production.

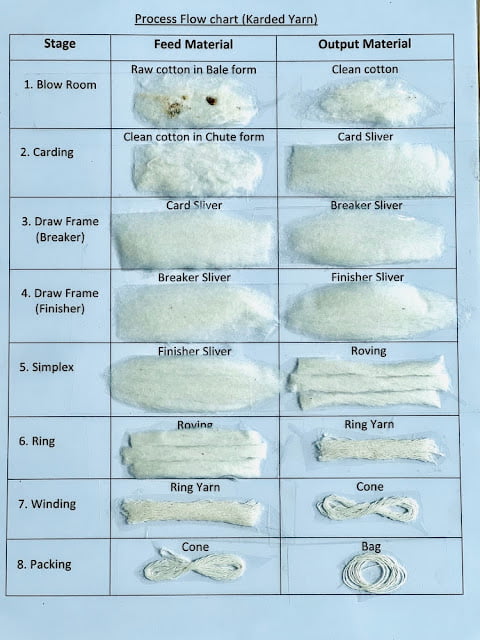

Process Flowchart of Carded Yarn Manufacturing

| Stage | Feed Material | Output Material |

|---|---|---|

| 1. Blow Room | Raw Cotton in Bale Form | Clean Cotton |

| 2. Carding | Clean Cotton in Chute Form | Card Sliver |

| 3. Draw Frame (Breaker) | Card Sliver | Breaker Sliver |

| 4. Draw Frame (Finisher) | Breaker Sliver | Finisher Sliver |

| 5. Simplex | Finisher Sliver | Roving |

| 6. Ring | Roving | Ring Yarn |

| 7. Winding | Ring Yarn | Cone |

| 8. Packing | Cone | Bag |

Conclusion

In conclusion, carded yarn is a versatile and unique type of yarn produced through the carding process, which involves cleaning, aligning, and blending fibres to create a consistent web or sliver of fibres. Carded yarn is commonly used in traditional hand-spinning and commercial textile production. Its ability to create unique textures and colors through fibre blending offers a wide range of creative possibilities.

You may also like: What is Carding? Definition and Meaning

Mainly used for Denim Fabrics.

I agree with your details , wonderful post.