Why Ring Spinning System is Universal | Technological Points in Blow Room

Last updated on September 21st, 2023 at 11:48 pm

Ring Spinning System is an Universal System

The ring spinning system is the most widely used system due to significant advantages in comparison with the new spinning process.

Ring spinning is the oldest of the present day spinning process. It is comparatively expensive than other spinning system because of its slower production speed and the additional processes (Roving and winding) required for producing ring spun yarns.

By this system we can produce wide range of yarn count with better quality. Any type of fibre can be spun in ring spinning system. Ring spun yarn quality depends upon the quality of raw materials, preparatory process and finally ring spinning machine. Today’s machinery is quite developed for the production of better quality yarn and for the productivity.

The fibres in the ring yarn are highly parallel and helical in nature and fibre arrangement is uniform along the thickness of the yarn. The high axial strength of the yarn is the result of unique self-locked structure.

The yarns made from ring frame have fewer naps, slabs, trash and are mostly fine yarn. So, from above statement I assume that, ring spinning is the best and universal.

The Basic Machines Required for Blow Room Line

- Opening M/C: To reduce tuft size.

- Beaters: To open and clean.

- Regulatory M/C: For uniformity of delivery material.

- Mixing and blending M/C.

- De-dusting unit: To separate the dust from the cotton.

- Metal detector: Heavy trash separator.

- Air flow: For transporting the material from one m/c to another.

State the Influencing Factors of Cleaning

- The longer the dirt particles, the better they can be removed.

- Opening should be followed immediately by cleaning if possible in the same m/c.

- The higher the degree of opening, the higher the better of cleaning.

- A very high cleaning effect is almost always purchased at the cost of a high fibre loss.

- There should be slightly less cleaning in the blow room and slightly more in card.

- Higher roller speed gives a better cleaning effect. But, also more stress on the fibre.

- Cleaning is made more difficult if the impurities are distributed through a large quantity of material by mixing with clean cotton.

- Damp stock cannot be cleaned as well as dry.

The Technological Points in Blow Room

- Opening in blow room means opening into small flocks from compacted. Technological operation of opening defines the volume of the flick is increased while the amount of fibre remains constant. I.e. the specific density of the material reduces.

- The bigger the dirt particle, the better they can be removed.

- Since almost every blow room machine can fully open particles, as far as possible a lot of impurities will be eliminated at the start of the process. Opening should be followed immediately by cleaning and if possible in the same machine.

- The higher the degree of opening, the higher the degree of cleaning. A very high cleaning effect is almost always purchased at the cost of a high fibre loss. Higher roller speed gives a better cleaning effect but also more stress on the fibre.

- Cleaning is made more difficult if the impurities of dirty cotton are distributed through a larger quantity of material by mixing with clean cotton.

- The cleaning efficiency is mostly depending on the Trash%. It is also affected by the size of the particle and gumminess of cotton. Therefore cleaning efficiency may vary for different cottons with the same trash%.

- There is a new concept called cleaning resistance. Different cottons have different cleaning resistance due to their properties.

- If cotton is opened well in the opening process, cleaning becomes easier because opened cotton has more surface area, therefore cleaning is more efficient.

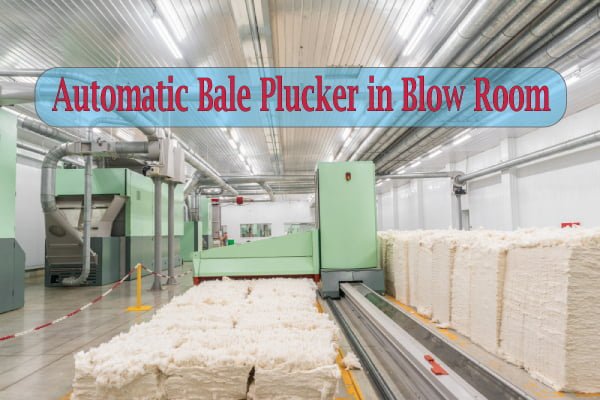

- If automatic bale opener is used, the tuft size should be as small as possible and the machine stoppage time should be reduced to the minimum level possible.

- If manual bale opener is used, the tuft size fed to the feed lattice must be as small as possible.

- Due to machine harvesting, cotton contains more and more impurities, which furthermore are shattered by strong ginning. Therefore cleaning is always an important basic operation.

- In cleaning, it is necessary to release the adhesion of the impurities to the fibres. The former is achieved mostly by picking of flocks; the latter is gained by leading the flocks over a grid.

- Using inclined spiked lattice for opening cotton in the initial stages is always a better way of opening the cotton with minimum damages. Of course the production is less with such type of machines. But one should bear in mind that if material is recycled more in the lattice, neps may increase.

- Conventional methods use more number of machines to open and clean natural fibre.

- Mechanical action on fibres causes some deterioration on yarn quality, particularly in terms of neps. Moreover it is true that the staple length of cotton can be significantly reduced.

- Intensive opening in the initial machine like bale breaker and blending machines means that shorter overall cleaning lies are adequate.

- In a beating operation, the flocks are subjected to a sudden strong blow. The inertia of the impurities accelerated to a high speed, is substantially greater than that of the opened flocks due to the low air resistance of the impurities. The latter are hurled against the grid bars into the waste box, while the flocks continue around the periphery of the rotating beater.

- By using a much shorter machine sequence, fibres with better elastic properties and improved spinnability can be produced.

- Air streams are often used in the latest modern machine sequence, to separate fibres from trash particles by buoyancy differences rather than beating the material against a series of grid bars.

- There are three types of feeding apparatus in the blowroom opening machines.

- Two feed rollers (clamped)

- Feed roller and a feed table

- A feed roller and pedals

- Two feed roller arrangements gives the best forwarding motion, but unfortunately results in greatest clamping distance between the cylinders and the beating element.

- Feed roller and pedal arrangement gives secure clamping throughout the width and a small clamping distance, which is very critical for an opening machine.

- In a feed roller and table arrangement, the clamping distance can be made very small. This gives intensive opening, but clamping over the whole width is poor, because the roller presses only on the highest points of the web. Thin place in the web can be dragged out of the web as a clamp by the beaters.

- Stickiness in cotton affects the process very badly. Because of that production and quality is affected. Particles stick to metal surfaces, and it gets aggravated with heat and pressure. These deposits change the surface characteristics which directly affects the quality and running behavior.

- There are chemicals which can be sprayed to split up the sugar drops to achieve better result. But this system should use water solutions which are not recommended due to various reasons.

- It is better to control the environment inside the department when sticky cotton is used.

- The easiest way to process sticky cotton is to mix with better cotton and to process through two blending machines with 6 and 8 doublings and to install machines which will segregate heavier particles by buoyancy differences.

Cleaning Point

There are several machines are remains in blow room lines for various purposes. But, these machines which are involved especially for cleaning the fibres is called cleaning point. In other words, beaters are called cleaning point. The names of cleaning points are:

- Step cleaner or, ultra cleaner.

- Porcupine beater.

- Kirschner beater.

- Cotton cleaner.

- R.N beater.

- S.R.R.L beater.

- Mono cylinder beater.

Metal detector

Magnets are used in blow-room line to remove iron/ irony substance from the cotton. These magnets are called metal detector.