Tearing Strength of Textile Fabrics

Last updated on April 23rd, 2024 at 03:01 pm

We prefer formal woven pants for official purposes, but most of us like to wear Jeans or Chinos for casual purposes. These dresses should look ok also should have the best quality. One of the most required qualities is its tearing strength. Different brands have different tearing strength requirements based on the fabric weight. In this article, we will know about the tearing strength determination process in ASTM D1424 method.

Tearing Strength of Fabrics by Falling Pendulum Type (Elmendorf) Apparatus (ASTM D 1424)

Field

This procedure only applies to woven fabrics (All types)

Purpose

This procedure describes the process for determining the force required to produce a single-rip tear starting from a cut in a fabric using a falling-pendulum (Elmendorf) apparatus.

Definitions

Tearing strength: The capacity of a fabric to withstand the tearing force required to produce tear after its initiation.

Apparatus and Equipment

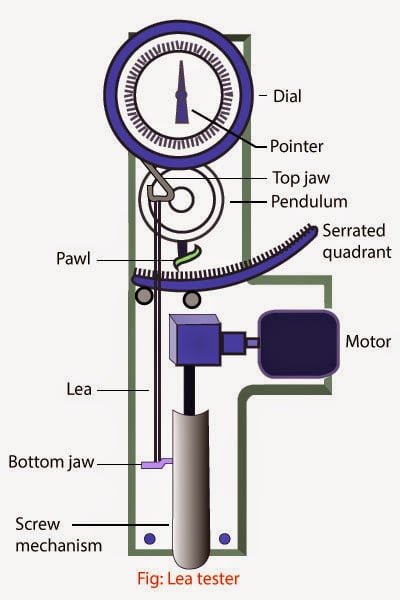

- Falling-Pendulum (Elmendorf) type tester.

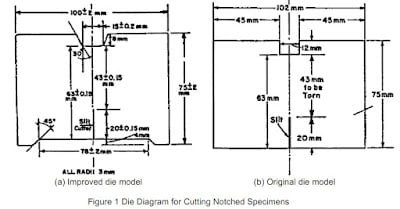

- Cutting die or Template (see Figure 1), the improved die model is shown in Figure 1(a) has two new features not found in the original model, Figure 1(b), namely a cutout for the bottom of the specimen to aid in centering it in the clamps, and (optional) provision for cutting the 20.0 mm (0.75 in.) slit before inserting the specimen in the tester.

Preparation of Test Specimens

- Four specimens are taken from the machine (warp) direction, and four specimens are taken from cross-machine (fill) direction from each sampling lot.

- When cutting the woven fabric specimens, align the yarn running in the short direction parallel to the die such that when the slit is cut, the subsequent tear will take place between these yarns and not across them.

- The specimens are conditioned at the standard atmosphere of 21 ± 1°C (70 ± 2°F), 65 ± 2% RH for at least 4 hrs before testing.

Test Procedure

- The pendulum is positioned to the starting position.

- One specimen in each direction should be pretested to determine the pendulum weight to be used before testing three specimens for each order.

- The specimen’s long sides are placed centrally in the clamps, with the bottom edge carefully set against the stops and the upper edge parallel to the clamps’ top.

- The clamps are closed, and the specimen is secured approximately the same tension on both clamps. If necessary, the pressure should be adjusted to prevent fabric slippage occurrence during the test.

- The specimen should lie free with its upper area directed toward the pendulum to ensure a shearing action.

- Using the built-in knife blade, a 20 mm (0.787″) slit is cut in the specimen extending from the bottom edge and leaving a balance of fabric 43.0 ± 0.15 mm (1.69 ± 0.005″) remaining to be torn.

- Record if the tear was crosswise to the standard (parallel) direction of tear and reported that specimen, or that sample, as applicable, as untearable.

- The torn specimen is removed, and the test must be continued until three tears are recorded for each test direction.

You may also like: What Kinds of Fabric Features Enable Clothes Become Comfortable to Wear?

Elmendorf tear definition refers to the phenomenon that yarn inside the fabric breaks one by one and tear the fabric into a crack when a part of the fabric edge is subjected to concentrated loading.

Greetings from Florida! I’m bored at work, so I decided to browse your site on my iPhone during lunch break. I love the information you provide here and can’t wait to take a look when I get home. I’m surprised at how fast your blog loaded on my cell phone .. I’m not even using WIFI, just 3G. Anyways, awesome blog!