Tear Properties of Fabrics (ISO 13937-2)

Last updated on March 28th, 2024 at 11:13 pm

In this article, we will see how to determine the tear properties of fabric in ISO 13937 part-02 method.

Definitions

Gauge Length

Distance between the two effective clamping points (grips) of a testing device is known as gauge length.

Equipments

- CRE (constant-rate-of-extension) a machine such as Titan.

- Clamping device, including the two jaws of the machine. The width of the jaws could preferably be 75 mm but not less than 50 mm.

Test Specimen

From each sample two sets of test specimens shall be cut, one set in the warp direction and one in the weft direction. Each set shall consist of at least three to five test specimens.

- The test specimen should be a rectangular strip (200±2) mm long and (50±1) mm wide.

- A longitudinal slit of (100±1) mm in length should be made beginning from the center of the width.

- Mark the end of the tear (25±1) mm from the uncut end of the strip to indicate the position of the tear at the completion of the test.

General: After wash, this test is not applicable so the test should be performed before wash.

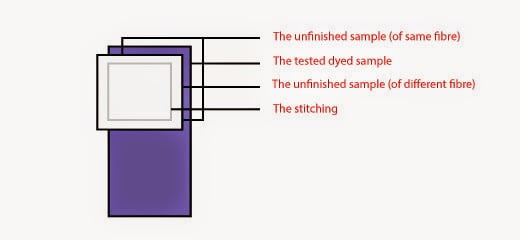

Treated denim: The denim which is scrapped or chemical treated should be tested before and after 3 washing & drying cycles.

Test only the treated and risky parts of denim, as for example, scraping, local bleaching. Several samples might be needed for testing.

Testing Procedure

The machine should have the following settings:

- Gauge length: (100±1) mm and Rate of extension: (100±10) mm/min

- Clamp the test specimen in the jaws, with one leg in each of the jaws and the cut aligned along the center lines of the jaws. The uncut end of the test specimen should be remained free. Avoid pretension when the test starts.

- Start the test and continue the tear to the mark near the end of the strip (point 1 in Pic 1). The tear force shall be recorded in newton and be calculated electronically. Observe whether the tear proceeds along the direction of force and whether any threads slip out from the fabric rather than being torn. The test is correct if there is; a. no slippage of threads out of the fabric; b. no slippage in the jaws; c. the tear is completed and preceded along the direction of application of the force. Other results should be discarded.

- The test result is only valid if a minimum of hree test specimens per set are correct.

Results

State following in the test report:

For denim: Report the lowest received tear force value across-warp and across-weft.

The number of test specimens rejected and reasons for this.

Any deviation from the given procedure (e.g. crosswise tear)

Hello there! This is my first comment here, so I just wanted to give a quick shout out and say I genuinely enjoy reading your articles. Can you recommend any other blogs/websites/forums that deal with the same subjects? Thanks.