Persons, who deal with fabrics, as well as the home sewing consumer, must be able to identify the warp and the weft or filling yarns, because the direction of the warp determines the way in which the fabric should be cut when a garment is made from it. In a new piece of cloth, the […]

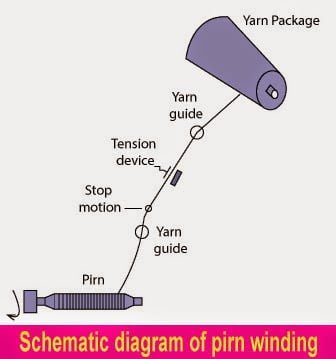

A Guide to Pirn Winding

Definition of Pirn A pirn or quill is a weft bobbin that is placed inside a shuttle in shuttle weaving. As the shuttle travels back and forth across the width of the shuttle loom, the weft yarn is unwound from the pirn through the eye (for ordinary shuttle) or slot (for automatic shuttle) of the […]

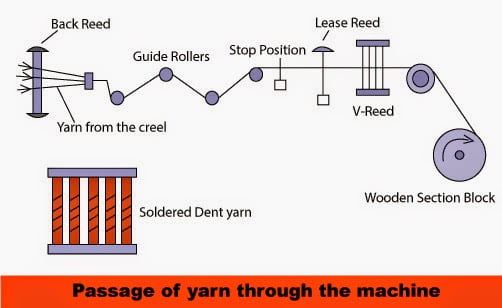

Sectional Warping Machine

Woven fabric is produced by the weaving process in the weaving mills. Sectional warping is an important process in these weaving mills. It is used to produce warp beams for weaving. So it is the preliminary process of weaving. In this article, we will learn about the sectional warping machine working process. Introduction The sectional warping […]

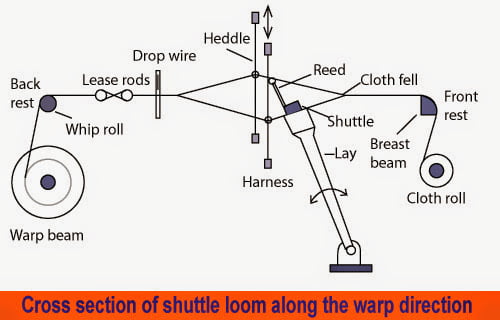

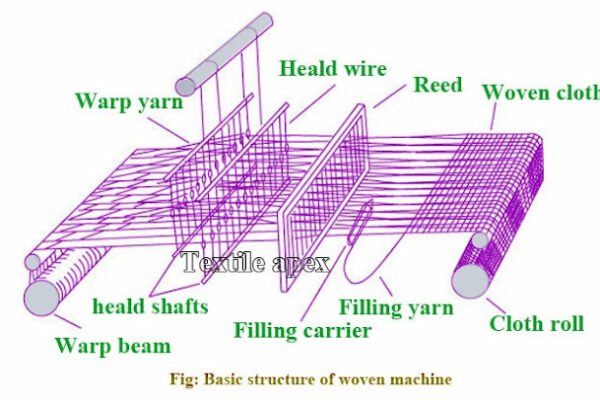

Different Parts of a Loom

Weaving is done on a machine called a loom. All the weaves that are known today have been made for thousands of years. The precise shape of the loom and its mechanics may vary, but the basic function is the same. Warp yarns are held taut within the loom, and weft yarns are inserted and […]

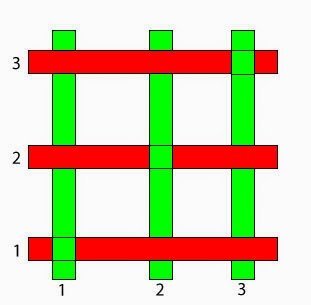

Some Important Terms of Fabric Structure and Design

The weave shows the interlacing pattern of warp and weft. Each weave consists of the following parts or fields. Contact Fields These are the contact points between warp and weft crossing at right angle. The number of contact fields always equals the product of the number of warp and weft threads. Contact field = RNwa X […]

Harness Mounting System of Jacquard Loom

Harness Mounting The jacquard harness is the system of cords, healds and lingoes that transmit the movement of the hooks to the individual warp threads. A simple form of harness is represented in the fig. below: There are two main types of harness ties. Norwich System When jacquard mechanism is mounted with the parallel of […]

Tappet Shedding: Definition, Types, Position and Construction

Definition of Tappet Shedding Tappet, Cam is the names given indiscriminately to those irregular pieces of mechanism. A rotary motion is given to produce reciprocating motion in the rod and levers for shedding. Types Tappet Shedding We can divide it into the following two types: Positive These give both upward and downward movements to healds […]

What is Beam Warping | What is Creel | Types of Creel

Definition of Beam Warping The warping process is intermediate between the winding and sizing processes. It produces the warper beams that are combined together as a single weavers beam in the next process of sizing. A warper beam may contain about 500-1000 warp ends. The direct or beam warping is suitable only for grey or monocoloured warps that require […]

Weaving Loom: Definition, Parts and Classification

Definition of Loom Loom is a machine or device which is used to produce woven fabric by interlacement of warp and weft yarn. Ginning, opening, cleaning, carding, combing, drawing, spinning, winding, warping, sizing, beaming are the process prior to weaving. All these process converge on loom. Classification of Loom Hand loom Power loom Different Parts of a Loom Short Description […]