Synthetic Fibre Production Process

Last updated on September 21st, 2023 at 10:35 pm

Synthetic fibre is a processed fibre where different processing steps are involved. It is not get naturally but through different mechanical processes. It is more durable than any natural fibre. It is also cheap in price. Synthetic fibre bought a revolutionary change in the Textile and Clothing industry.

Though it is not easy to dye but after dyeing we get the best colorfastness properties. Synthetic fibres can be dyed to any type of shade. Finer to any coarser count yarn is possible. So fashionable products have become easy to make.

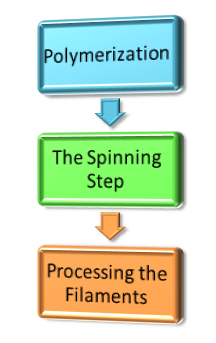

Synthetic Fibre Production System

In the manufacture of any synthetic fibre three general process steps are required to produce a finished product:

- Chemical intermediates are polymerized;

- Filaments are spun from the polymers; and

- The untreated filaments are processed to prepare them for use by the textile industry.

Polymerization

Chemical compounds which serve as raw materials for synthetic fibres do not possess the fibre-forming property until they first undergo a chemical reaction called polymerization. To polymerize is to change a chemical compound, by union of two or more molecules of the same kind, into a higher molecular weight compound having different physical properties. The product of the reaction is called polymer.

Polymers of low or average molecular weight cannot be made into commercially usable fibres; rather, the fibre-forming polymers consist of molecules of very high molecular weight, often called “macromolecules.” How such large molecules can be built up is generally explained by the theory that monomer (single) molecules are joined together in long chains. Thus it can be said that in the first step in fibre output polymers with long chain link molecules are synthesized.

Before it becomes a polymer a chemical intermediated is a monomer, the term for the simple non polymerized form of a compound. Thus it can also be said that the first step in synthetic-fibre manufacture is to make polymers out of monomeric raw materials.

In the manufacturing plants there is an area, usually designated the “polymer area, in which the conversion is carried out as a batch or as a continuous process. Quantities of the monomeric raw materials are fed into polymerization reactors under pressure, temperature and duration conditions which vary with the monomers.

The Spinning Step

Three spinning technologies are used to make filaments from synthetic polymers: dry spinning, wet spinning, and melt spinning. In all these methods filaments are formed by forcing a viscous polymer through a spinneret, a small die like plate with many fine holes. In the preparation of the polymer for spinning and in the solidification of the newly formed filaments the spinning methods differ in detail.

Dry Spinning

In dry spinning the polymer is dissolved in an organic solvent to form a spinning solution which is extruded through a spinneret into a long tubular spinning cell through which hot air is circulated. The filaments are solidified by the evaporation of the solvent.

Wet Spinning

For wet spinning a solution is prepared in the same way, but it is extruded through a spinneret into a spinning bath capable of coagulating the filaments.

Melt Spinning

In the production of synthetic fibres which can be “melt” spun the preparation of a spinning solution is unnecessary. Molten polymer is forced through the holes in the spinneret by pump action, and the filaments solidify upon contact with a stream of cold air.

The spinning area of a synthetic fibre plant contains several spinning machines or spinning batteries, each with multiple cells for filament production.

Processing the Filaments

After the polymers are spun, the process steps depend on the output mix of the fibre plant. In the production units under consideration here man-made fibres are produced in three different forms for sale to the textile industry – as continuous filament yarn, as staple fibre, or as tow.

Synthetic filament yarn consists of a number of fine continuous filaments. For sale to ultimate users it is put up on bobbins with no twist or a light twist.

Staple fibre is made by cutting up the continuous filaments into short lengths and is sold in bales to the textile industry for the manufacture of spun yarn.

Spun yarn can also be made from tow, the third form in which synthetic fibres are sold. Textile spinners with traditional spinning equipment must use staple fibre in spun-yarn manufacture. Tow is a collection of many parallel continuous filaments, grouped together in ropelike form and put up into packages without twist. It is sold to manufacturers who have special machines designed for the direct production of spun yarn from tow. The tow is mechanically broken up into short lengths, and the yarn is prepared by methods which eliminate many of the steps in the staple-to-yarn process.

At the present time nylon-66, Orlon, and Dacron are produced in all three forms, but Acrilan and dynel are being manufactured only as staple fibre and as tow. How the various forms of synthetic fibre are made is dealt with in the sections devoted to the manufacture of each fibre.

You may also like: Factors of a Model Textile Fibre for Spinning

I believe there are many more pleasurable opportunities ahead for individuals that looked at your site.

Dear this is very useful information for those who can not take these information from someone explained detailed easy to understand thanks alot love from Karachi :hassan shahzad