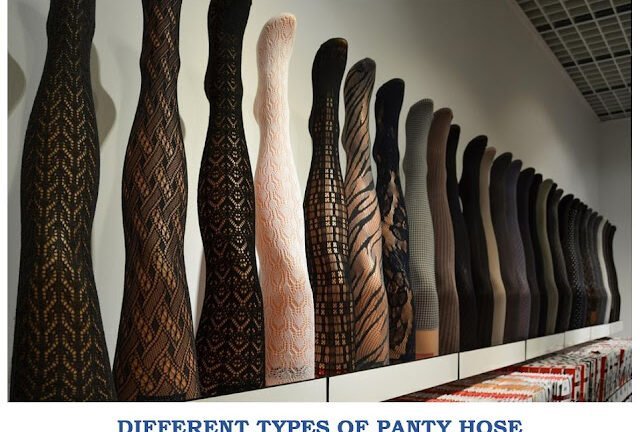

An overview of Pantyhose

Women’s sheer nylon hosieries are made of filament nylon yarn. The yarn may be a stretch or bi-component type to provide increased elasticity. Spandex may be added for greater elasticity and support. The hosieries are ….. Read More