What is Carpet? Construction of Carpet

Last updated on July 22nd, 2023 at 10:59 am

Definition of Carpet

Carpet that comes in specific sizes is sold by the yard and housed in rolls. They are also produced at various price points and styles. It is available for household use and heavily trafficked areas that necessitate commercial grades. The typical rolls of carpet are produced in a wide range of standard and fashion colors that will fit almost any designer’s need or in custom colors and patterns for more unique settings.

Construction of the Carpet

When it is initially chosen for home or commercial use, it is generally selected on the basis of appearance. Of course, price and durability are also important factors in their ultimate section. Before the final decision is made, several factors should be considered. Construction is one of them.

It is constructed in many ways, including tufting, weaving, needle punching, flocking and knitting.

You may also like: An Overview of Different Types of Lightweight Fabric

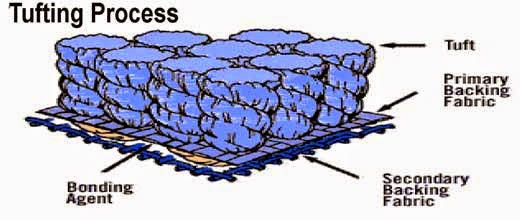

Tufting

The vast majority of carpet made today is made by tufting process. The procedure involves the sewing or punching of face pile yarns into a backing by a special machine that is equipped with numerous needles. The tufts are inserted lengthwise into a primary backing. In finer carpet the tufts are close together, giving the finished product a denser quality and appearance. The tufts are then set in place with the use of a latex compound that is laminated to the secondary backing. This final backing or layer gives the carpet additional strength.

The primary backing is used in tufted carpet is usually made of polypropylene. For fine gauge, polyester is sometimes used in place of polypropylene. The secondary backing for tufted carpet is also mostly made of polypropylene, with jute or foam used to a lesser extent.

Weaving

Woven carpet has been available for many centuries. Before the invention of machines, the products were handwoven. The process for both is virtually the same, with different types of weaves used for specific appearances and qualities.

Basically, to produce a woven carpet, two sets of yarns are intertwined. These are the pile yarns, commonly referred to as face yarns, and backing yarns that result in a single “fabric.” The three most common types of woven carpets are velvet, Wilton, and Axminster.

- Axminster is a machine-woven carpet that features an enormous number of colors and colorful patterns.

- Wilton is a woven carpet made in a variety of patterns and textures but with a limited number of colors in the patterns.

- Velvet carpet features a level surface or cut pile and is made of yarns that have a very little twist.

Needle Punched

Needle-punched construction requires the assembly of fibre webs that are compacted and interlocked by means of barbed felting needles. The advantage of this type of construction is that it can be printed, flocked and embossed, the latter giving it textural effects. The angling of the needles and the mixing of fibre deniers (weight) produce textures such as corduroy. After the carpet has been woven, weather-resistant latex is applied to the back. The process is relatively low cost and is used primarily for indoor/outdoor carpets.

Flocking

Few carpets are made with the flocking process. The appearance resembles velour and offers a product that is resilient and crush resistant. The “fabrics” are usually backed with a secondary backing material to add body and dimensional stability. It is sometimes used for bathrooms.

Knitting

The process is done on a knitting machine, and when finished, is backed with a coat of latex and secondary backing material to provide stability and strength. It is used in a small percentage of carpet production.

Sculpturing

A variation of weaving technique, sculpturing produces a multilevel loop carpet. Two sets of loops are woven into the carpet; the taller ones are sheared and the shorter one remains uncut to produce a sculptured pattern. This textured carpet, often with variegated coloring, has the added advantage of camouflaging soil.

You may also like: What is Flock Printing | Flock Application Methods

Thank you for posting this article. I will share this with my team.

I want to thank you for your assistance and this post. It’s been great.