Functions of Different Regions of Card

Last updated on August 20th, 2023 at 11:51 pm

Carding is an essential section of a spinning mill. Because without carding different types of yarn count is impossible. Also fineness of yarn is impossible. In this article we will discuss about the functions of different regions of Carding section.

Task of Feed Region

- To clamp the flock securely over its full length.

- To hold the material back against the action of taker in.

- To protect the flock to the taker-in such a manner that opening can be carried out gently.

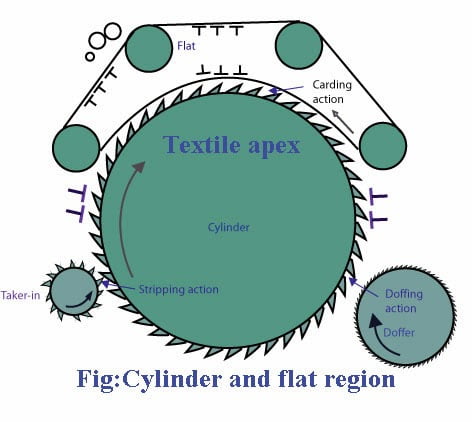

Taker-in Region

- To unwind lap or flock for continuous feed without uncontrolled stretching.

- To eliminate impurities.

- To transfer the fibres as evenly (both transversely and longitudinally) as possible.

- To perform the primary opening and cleaning.

Different Parts of Cylinder Region

Back Plate:

- To hold the fibres on the cylinder.

- To prevent the development of undesirable air current.

Top feather plate(edge size):

- To control the weight and thickness of the flat/feed sheet.

Cylinder stripping door:

- Used to strip wire point of cylinder.

Bottom sheet:

- To hold the fibres on the cylinder.

- To prevent the development of undesirable air current.

Cylinder under casing:

- Removes dirt and fly.

- Maintain constant air flow.

The Flat Region

- Opening the flocks to individual fibres.

- Elimination of the remaining impurities.

- Elimination of the short fibres.

- Disentangling the neps.

- Removes the dust.

- Perform high degree of longitudinal orientation of the fibres.

You may also like: What is Carding? Objects and Tasks of Carding

Thanks for one marvelous posting! I enjoyed reading it; you are a great author.I will make sure to bookmark your blog and may come back someday. I want to encourage that you continue your great posts, have a nice weekend!