Flat-Screen Printing Method (Carpet)

Last updated on August 4th, 2023 at 08:08 pm

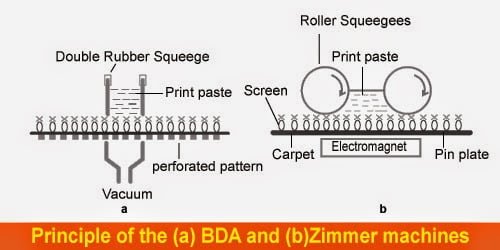

Penetration into the pile is important in carpet printing and there are two principles upon which flat bed machines have been constructed. The BDA machine, which is no longer widely used, employed an ingenious arrangement in which the reservoir of dye was trapped between the blades of a double squeegee passing over the screen, penetration of the pile being assisted by the application of a vacuum from beneath (Fig: a). In the Zimmer machine the print paste is trapped between the electromagnetic roller squeegee (Fig: b).

Penetration in this case is encouraged by the pressure created by the second roller running over the wedge of paste, which is traps as it moves forward over the screen. Shorter pile lengths are preferred for this machine. There are also other versions of the rotary-screen printing machines with heavier gauge screen and rollers.

A more novel method for applying color to carpet substrates is through the use of a bank of miniature jets of dye. This principle was first used in the Millitron machine of Milliken & Co., although other similar machines are now available. The jets are controlled by computer operated electromagnetic valves, and the mechanism has eliminated the need for screens. Since there is no distortion of the pile, optimum surface appearance is maintained and the pattern can be changed simply by the use of different computer software.