Fabric Shrinkage Test

Last updated on July 6th, 2023 at 11:03 am

When we give a knitted T-Shirt for laundry or wash, we can discover that the T-Shirt has become smaller than its original size after laundry or washing. This happens due to Fabric Shrinkage. It is a process in which fabric dimension becomes smaller than its original size. It happens either lengthwise or width wise or both.

It depends on various factors such as raw material, fabric making procedures, finishing etc. As for example, fabrics made from natural fibres tend to be more shrinking than synthetic fibres. This property affects the finished garments or product the most, as it can potentially distort the shape of the garment in different degrees. So it is better to test the degree or percentage of fabric shrinkage.

Fabric Shrinkage Test Procedure

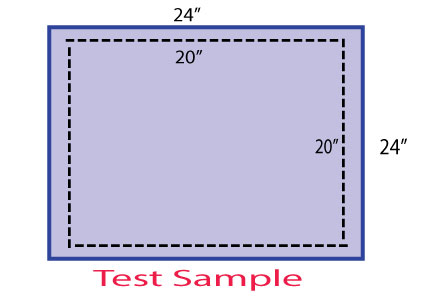

A sample of test specimen measuring 24 inch X 24 inch should be taken and marked with different color sewing thread by 20 inch X 20 inch. The specimen sample should be laid flat without tension on a smooth flat surface in the standard testing atmosphere (65% R.H & 680F) at least for 18 hours. Reference measurement should be taken carefully and accurately.

Then test specimen should be put into the washing machine. Temperature should be put into 380 C. Sodium carbonate and neutral wetting agent shall be added in quantities to give a solution containing 0.1% each. The weight of the specimen shall not exceed one half pound per gallon of washing liquor. The washing machine shall be set in motion and kept running without interruption until the washing and rinsing of the specimen are completed.

After running the machine for 15 minutes the washing liquor shall be drained off. After that the specimen shall be washed for 5 minutes three times each at 380C.

The specimen shall be taken out from the washing machine and folded to form a pad having 8 layers and laid against the side of the hydro-extractor machine. The hydro-extraction should be carried out for 10 minutes to remove excess water from the specimen. Then the specimen should be taken out from the hydro-extractor and kept for few minutes to equalize the distribution of remaining water inside the sample.

Then the specimen shall be laid flat without stretching on the pressing table and pressed with heated iron for 30-40 second and moving the iron without sliding to an adjacent position and repeating this process till the whole area of the specimen become dry. After pressing the sample should be reconditioned and measurement should be taken.

Shrinkage test result should be expressed in percentage for both warp and weft way of the fabric.

Very informative blog .