Last updated on September 11th, 2023 at 10:43 pm

Sewing Thread

Almost all garments produced have one component in common: the sewing thread. Whilst sewing threads are usually a relatively small percentage of the cost of a garment, they have an extremely significant influence on the appearance and durability of the finished product. The production of sewing threads is an extensive and complex subject.

In practical terms, any examination of sewing threads must start with the question, what are the essential requirements of sewing threads? The answer can be grouped under two headings, sew-ability and durability.

Sew-ability

This describes the basic all-round properties of the thread, including:

- Not breaking when used for high speed sewing.

- Facilitating the consistent formation of stitches.

- The minimum occurrence of skipped stitches.

- In order to prevent changes in tension during sewing, the thread must have a uniform diameter.

- A high level of resistance to abrasion is essential due to the friction of the thread in the needle eye and with other mechanisms.

- The thread has to have sufficient surface smoothness to pass easily through the guides on the machine. This ensures the uniformity of stitch formation.

Durability

The main thread related factors under this heading are:

- The thread has to have sufficient elasticity to withstand the normal pressures imposed on seams during wear. This is particularly important for knitted fabrics because of their inherent extensibility.

- Thread shrinkage should minimal after the garment has been washed or dry-cleaned. Seam puckering is often caused by unstable thread.

- It is important the thread maintains its original color after being subjected to cleaning processes. In particular, this applies to the threads used for top stitching and other decorative purposes such as embroidery.

Thread Types

Ideally a sewing thread should combined the best properties of sew-ability and durability, and whilst there are many threads available which approach this, certain compromises have to be accepted due to various technical limitations. However, for practical purposes sewing threads for the clothing industry can be divided into three broad groups: Cotton, Synthetic and core-spun.

Cotton

Threads made from cotton fibres have excellent sewability because the fibres are very supple and are not seriously affected by the heat generated by needles during sewing. On the other hand, cotton threads are not highly durable and some of the softer types have a tendency to shrink when the garment is washed. Glace and mercerized cotton threads sew well and have a lustrous appearance, but they both shrink slightly when wetted.

Synthetic

This is a large group of threads made mainly from nylon, polyester, rayon and polyamide filaments or fibres. The threads are very durable and are not affected by moisture or the chemicals used in washing powders or dry cleaning solvents. In addition, they have excellent dimensional stability and a high level of resistance to abrasion. Synthetic threads are available in a number of different constructions and finishes, which enhances their performance for special sewing applications.

Core Spun

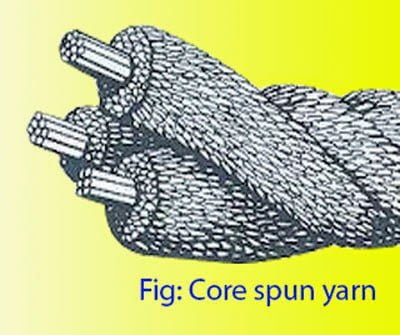

This thread has a continuous filament polyester core wrapped in cotton fibres, which produces a strong thread with excellent sew ability.

Core spun threads have good elasticity and a high resistance to heat and shrinkage, but cost more than regular threads because they have to be dyed twice, first for the polyester core and then for the cotton wrap. An advantage of core spun threads is that finer threads can be used due to the superior strength of the polyester core.

Other fibres

Two other natural fibre threads which have limited applications are silk and linen.

Silk

These threads are strong, with good elongation and a highly lustrous appearance. Silk threads have good sewability but the high cost restricts their use for mass production sewing.

Linen

Once widely used for sewing tents, shoes, leather etc, threads spun from flax have been mostly replaced by synthetics.

Thread Sizes

There are many systems for defining thread size but the most widely used is the Tex number system. This is based on the gram weight of 1000m of yarn, so a fine thread would have a low Tex number and a thick thread would have a high number. Thread manufacturers using other systems will normally provide the Tex equivalent values.

Costs

Price is not necessarily the sole criterion for purchasing sewing threads because it is performance which really counts. Trouble-free sewing combined with durability is essential to prevent constant work stoppages caused by continual breaks, and to avoid consumer dissatisfaction with seams that open during normal wear conditions.

Effective sewing can only be achieved when there is an accurately balanced combination of all the components involved. It is said that the real strength of a chain is that of its weakest link, and this also applies to sewing.

You may also like: Garment Seam Pucker: Types, Causes and Remedies

Thanks.

It’s great to come across a blog every once in a while that isn’t the same out of date rehashed material. Fantastic read.