Determination of Colorfastness to Wash of a dyed fabric in ISO method

Last updated on July 18th, 2023 at 11:28 pm

Introduction

Colorfastness is a term used in the dyeing of textile materials color to fading or running. The term is usually used in the contact of clothes. In general, clothing should be tested for colorfastness before using bleach or other cleaning product.

Lightfastness, wash fastness and perspiration fastness are the main ones that are standardized color fastness are the resistance of color to fade or bleed by some agencies like washing, light, water, chlorine, perspiration, ironing etc. Dyed and printed materials may lose their color for the following reasons:

- Due to decomposition of dye molecule in the fibre (as light fading).

- Due to reaction with acid, alkali or perspiration (as in perspiration fastness).

- Due to friction of outer surface (as in rubbing) colorfastness is usually assessed separately with respect to –

a. Change in color of specimen being tested with color fading.

b. Staining of un-dyed materials which is in contact with specimen during that is color

bleeding.

Fastness property of a dyed sample

The outstanding important property of a dyed material is the fastness of its shade. There are various types of fastness as below:

- Colorfastness to light.

- Colorfastness to wash.

- Colorfastness to water.

- Colorfastness to rubbing.

- Colorfastness to perspiration and so on.

The above five tests are very important and they are done according to buyer requirements.

You may like also: Different Tests for Textile Quality Control

Colorfastness to Washing

The resistance to the loss of color of any dyed or printed material to washing is preferred to as its wash fastness. If dye molecules have not penetrate inside the interpolymer chain space of fibre or have not attached to the fibre with strong attractive force, poor washing fastness result.

There are five ISO recommended wash fastness tests namely:

- ISO test no. 1 was formerly known as the handwashing test.

- ISO test no. 2 was formerly known as S.D.C test no. 2

- ISO test no. 3 was formerly mechanical washing.

- ISO test no. 4 was formerly known as mechanical washing test – B.

- ISO test no. was formerly known as S.D.C test no. 4

The first three methods are done in the same procedure at different distance temperatures. The last two methods are also the same procedure but differ in time duration.

Instruments and Materials Needed for Washing Test

- SDC recommended multi-fibre fabric: To meet AATCC standard color fastness tests to washing, perspiration and others. This product has a repeat of Acetate, Bleached Cotton, Nylon, Polyester, Acrylic and Wool fibre yarns.

- Water shaking.

- Dryer.

- Color matching Cabinet.

- Sewing machine.

- Greyscales.

Reagents Required for Washing Fastness Test

- ISO reference detergent.

- Sodium carbonate.

- Distilled water (Grade – 3) etc.

Recipe

ISO – Method – 2

ISO reference detergent = 5 gm/L

M : L = 1 : 50

Temperature = 50/520C

Time = 30 min

Sample = 1.03 gm

Necessary Calculation

Reference detergent = 10%

Stock solution = (5 X 10 X 100)/(1000 X 10) = 5 CC

Water required = (51.5 – 5) CC = 46.5 CC

Preparation of Test Specimen

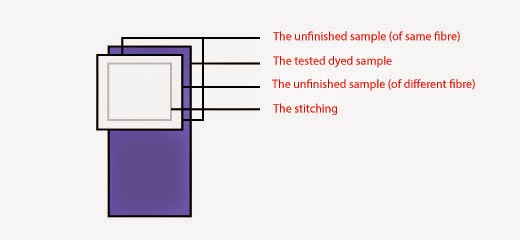

A sample of dyed fabric of size 10cm X 4cm is cut and placed between two un-dyed, unfinished samples of size (5 X 4)cm2 and sew both side of the fabric. The un-dyed unfinished sample of size (5 X 4)cm2 were cotton fabric. This called a composite test sample.

The test Procedure for Washing Fastness

The composite sample is treated in a water shaking bath for 30 minutes at 50 or 520C with a stock solution and required water. After testing for 30 minutes, the sample is taken away from the washing solution. The sample will be rinsed twice in cold distilled water and washed in running cold water for 10 minutes. Then the sample is squeezed carefully. Stitching is removed on two long sides and one short side. The sample is now dried at 600C at tumble dryer. The contrast between the treated and untreated sample is compared with color change greyscale and staining of adjacent fabric is compared with staining scale in color matching cabinet.

Result

Color change in shade – Grade 4 (good result)

Color staining in cotton – Grade 4/5 (good result)

Precautions

- The sample should cut correctly and carefully.

- The solution should be prepared accurately.

- Time should be maintained.

- The sample should be viewed properly and rated accurately.

Remarks

After the washing test, we can say that the washing fastness quality of the treated fabric is good. Washing fastness is maintained according to buyer requirements.

When is the published date of this?

Hey, I have been searching for knowledge about Light Fastness Tester for a long time and have found your helpful post! Thank you!

It’s always so sweet and also full of a lot of fun for me personally and my office colleagues to search your blog a minimum of thrice in a week to see the new guidance you have got.