Description of a Precision Winder

Last updated on August 9th, 2023 at 12:44 am

Precision Winder

The main feature of precision winder is the spindle in which the package is mounted and it directly gets drive. The precision winder is one, in which there is a constant ratio between the speed of the spindle which carries the package being wound and the speed of the traversing mechanism.

This winder has the capacity for winding almost all types of yarn such as cotton, rayon, synthetic, spun rayon, linen etc. Besides, fineness and quality of the yarns do not offer any difficulty in winding on this machine. Even fine denier nylon can be wound on it without any practical difficulty. The types of wind that can be produced on this machine are close and open wind. The number of winds obtainable ranges from 40mm to 100mm.

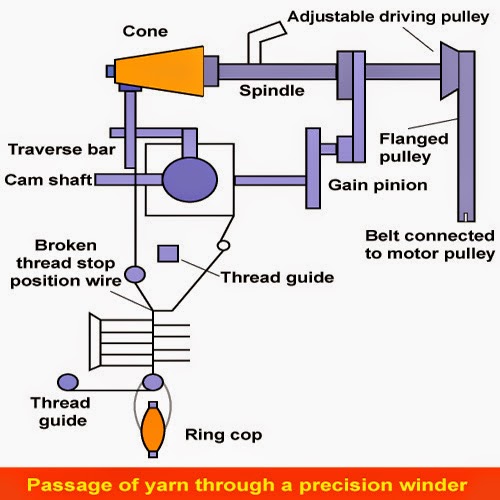

The passage of material through the important parts of the machine is shown in the following figure –

The yarn from the supply package passes through the thread guide and on the gate type of tensioner. The tension of the running yarn is easily adjustable to suit the requirements. The machine is provided with a thread stop motion which stops it in the event of a yarn breakage or exhaustion of supply package. The yarn then passes to a traversing guide. The traverse guide consists of a steal roller plated with chromium, which is a hard metal. As such, it will prevent wear to a very great extent. The traverse bar, to which the guide is attached, makes back and forth movement through

a guide provided with self oiling arrangement. The important parts of the traverse motion are fully enclosed to prevent accumulation of dust and dirt which may affect its correct functioning. The cam is fully enclosed in an oil box to keep it lubricated all the time by the splash of the oil. The setting of the dog segment permits fine adjustments. The winding pressure can also be regulated with precision according to requirements. The tapering of the cone can be regulated to the desired extent by means of an indicator device provided on the machine. The winding speed of the machine can be adjusted from 200 to 400 meters/minute to suit yarns of different qualities and counts.

- For cotton the yarn speed is 400 m/min

- For spun rayon the yarn speed is 400 m/min

- For nylon the yarn speed is 350 m/min

The spindles are located in horizontal position and get their drive from the motor. The spindle rotates at a constant speed and hence the package will increase in diameter, so the yarn tension will also increase, which in turn will increase the elasticity of the yarn. To avoid this defect the tension of the yarn is reduced and the diameter of the package is increased.

The various arrangements described above enable the machine to wind yarns with different characteristics. Although it is specially designed for producing delicate man-made fibres like nylon, terylene etc., the machine can be employed for fine cotton yarns where the conditions are favorable for its use.