Cotton Vs Organic Cotton: Find the Key Differences

Last updated on January 8th, 2026 at 02:48 pm

We are so much concerned about our outlook and fashion brands. We always want to choose fashionable clothing products for us. We like to choose our favourite clothing products depending on season, design and comfort. For all seasons, cotton products are preferable.

It is a matter of sorrow that we like to use cotton products, but most of us don’t know how cotton is produced and what the environmental consequence of producing cotton is.

But it is a matter of hope that we’ve already started to be conscious about organic food and organic and also about organic clothing. When organic clothing comes to mind, then the term which comes first is “organic cotton”.

The term “organic cotton” is confusing, as most of us think that cotton and organic cotton is the same thing. But there are many differences between cotton and organic cotton.

Definition of Cotton

Cotton fibre is a pure natural cellulosic fibre. It grows in a protective case around seeds on a cotton plant. It is soft, cool and known as a breathable fibre and is also absorbent. It can hold water 25 times its own weight. It is strong, dye absorbent and can stand up against abrasion wear and high temperature.

Definition of Organic Cotton

The definition of organic cotton and cotton is the same, but the only difference is just the production process. Organic cotton is cotton that has been grown for at least three years without chemical pesticides, defoliants, or fertilisers. Natural fertilisers and fertilising techniques are used instead, including compost, manure, naturally derived mineral and plant fertilisers, and crop rotation.

Cotton Processing

The exact origins of the cotton plant are unknown, although archaeologists have unearthed pieces of cotton cloth over 7,000 years old. Through the centuries, cotton fibre was traditionally processed by hand until the early 18th century, when the first automated processing machine was invented.

Before cotton arrives at the textile mill to be spun into yarn and woven into fabric, it makes the journey from field to bale. Cotton takes about five months to grow from a planted seed to a ripe plant.

A harvesting machine, called a cotton picker, plucks fluffy seed cotton out of the plants’ boll, leaving a trail of burrs and sticks behind. The machine empties the plucked cotton into a tractor-drawn buggy. This machine builds the seed cotton into a humongous rectangular block called a module.

A truck transports the module to the processing plant, known as a cotton gin. Once the cotton arrives at the processing plant, sticks and burrs are removed, as well as any lingering debris and seeds.

A truck dumps the module into a feeder, which moves the packed seed cotton into a dispenser. The ground seed cotton falls onto a conveyor belt, which leads to the hot box. The hot box mixes the seed cotton with hot air, which allows the moisture to evaporate, making the seed cotton easier to clean.

A machine called the ‘wad buster’ breaks up the clumps of seed cotton by tossing it against a screen. Loose debris falls through the screen openings down a narrow chute.

Then the seed cotton moves through a machine called the steady flow, which divides it equally between two processing lines. On each line, the seed cotton enters a burr machine, which grabs the seed cotton with a circular saw and swings it against metal bars. The centrifugal force shakes off the heavier debris. The seed cotton exits the machine through one pipe and the debris through another. A large auger transfers the debris to a waste chute and out of the plant. The seed cotton is ready for the final stage of processing.

A network of pipes feeds a row of machines called gin stands. The gin stand separates the seed from the fluffy stuff, called the lint. Inside each stand are 116 circular saws, which are arranged horizontally, each separated by a steel rib. The saw teeth grab the seed cotton and pull the lint through the narrow gap between the saw and the rib. The seeds are too large to pass through, and so they spin in front of the rib and then drop into a conveyor. The lint goes into a flue, which leads to the packing area.

Cotton seed is sold as livestock feed, particularly for dairy cows. It contains 23% protein, 20% fat, and 25% fibre. Cotton seed is also milled into cottonseed oil, a cooking oil that’s a common ingredient in salad dressings and mayonnaise.

The cotton lint is now ready to be formed into bales. Pipes feed the loose lint to the press area. When it arrives, a pusher moves the lint into a machine called the tramper, which shoves it down into a bale-shaped box. Once the box reaches 500 pounds of cotton lint, a press compacts the lint and tie-wraps the bale.

Next, a conveyor moves the bale to a bagging machine and past grippers, which pull a sample from each side. While the bale slides into a protective plastic bag, the grippers deposit the sample into a bin. Technicians label the bale with an i.e. number and then open the bin to retrieve the corresponding sample. Then the sample is bagged and labelled with the bale, i.e., number. The factory submits the sample to the laboratory, where it’s analysed for fibre length, cleanliness, colour, and other criteria. Once the analysis is complete, the bale is given a grade and processed accordingly.

Difference between Cotton and Organic Cotton

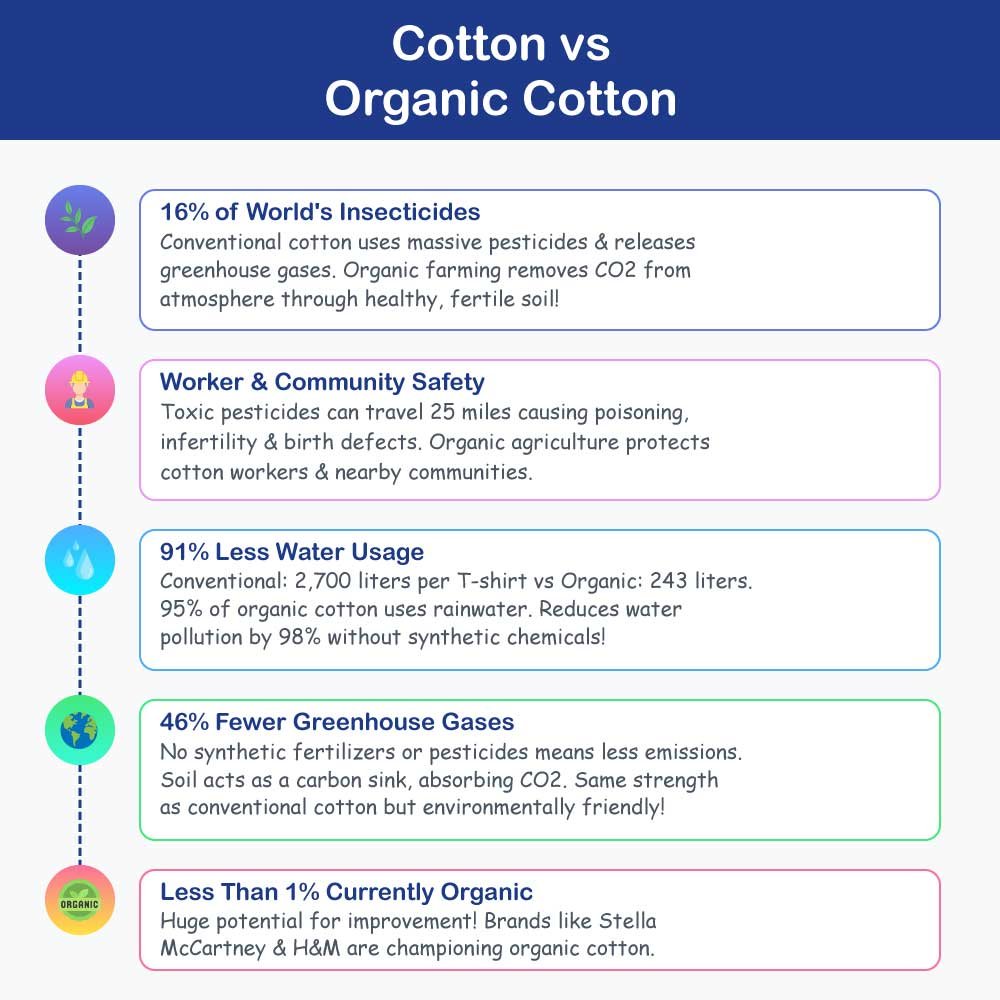

- Conventional cotton is the most heavily pesticide-sprayed crop. It uses a massive 16% of the world’s insecticides and puts greenhouse gases into our atmosphere. By avoiding pesticides, organic farming not only keeps the air cleaner but also actually removes CO₂ from the atmosphere thanks to healthy, fertile soil!

- Toxic pesticides used in conventional farming can travel up to 25 miles in the air and water streams, causing health problems such as poisoning, infertility and birth defects. Organic agriculture keeps damaging chemicals away from cotton workers in the fields and protects communities nearby.

- Organically grown cotton is seen as environmentally friendly, as no synthetic fertilisers, pesticides and herbicides are used in the growing of the cotton. Environmental stewardship is increasingly in the public eye, and the use of organic cotton has become very trendy among consumers. Manufacturers and retailers are responding to their demand for more “natural” products.

- The physical properties, such as strength, do not differ from that of traditional cotton.

- According to the WWF, it takes 2,700 litres of water to produce the cotton needed to make just one T-shirt. However, organic cotton — generally produced without synthetic chemicals, such as fertilisers and pesticides — is a different story altogether. The Soil Association says it uses only 243 litres by comparison. As a result, an increasing number of fashion brands, from Stella McCartney to H&M, are championing the natural fibre.

- Less than one per cent of all cotton produced is currently organic, meaning there is huge potential for improvement when it comes to how we make the fibre.

- According to a 2017 report by the Textiles Exchange, organic cotton uses 91 per cent less ‘blue’ water (from groundwater and surface-water bodies, such as freshwater lakes and rivers) than conventional cotton.

- The majority of organic cotton is grown on small-scale farms, which tend to be rain-fed rather than irrigated and, because they don’t use synthetic pesticides and fertilisers, don’t need to use as much water. Organic cotton doesn’t involve genetically modified crops, which generally require more water, while pesticide-free soil also makes the process more water-efficient. In fact, 95 per cent of the water used to grow organic cotton is green water (rainwater and water stored in the soil).

- Growing organic cotton, rather than conventional cotton, also reduces levels of water pollution by 98 per cent, according to a 2011 report by the Water Footprint, as synthetic chemicals such as pesticides and fertilisers aren’t used.

- According to the Textile Exchange, organic cotton creates 46 per cent fewer greenhouse gas emissions than conventional cotton simply by not using nitrous dioxide-releasing fertilisers and pesticides and using fewer mechanised farming practices. By virtue of being fertiliser- and pesticide-free, the soil also acts as a ‘carbon sink’, absorbing CO₂ from the atmosphere.

You also like Cotton vs wool – which one is more comfortable?

Very good article to differentiate betn ctn & org. ctn.

Nice comparison…. Thanks for sharing.

Best so far

Thanks bro.

Thanks

Thanks…be with us.

Nice information. Thanks for sharing bro.

Welcome brother.

The best info…

Thanks

Good comparison.

Thanks.

So informative article…

It is a very informative article. It appears to me that there is no difference between actual plant that is grown as organic and non-organic. If that is true, why not grow all plants as organic with 90% reduction in water. There must be some financial benefit in growing non-organic cotton plants.

Your thinking is absolutely right.Thanks for your valuable comment.

Thank you Abu Sayed