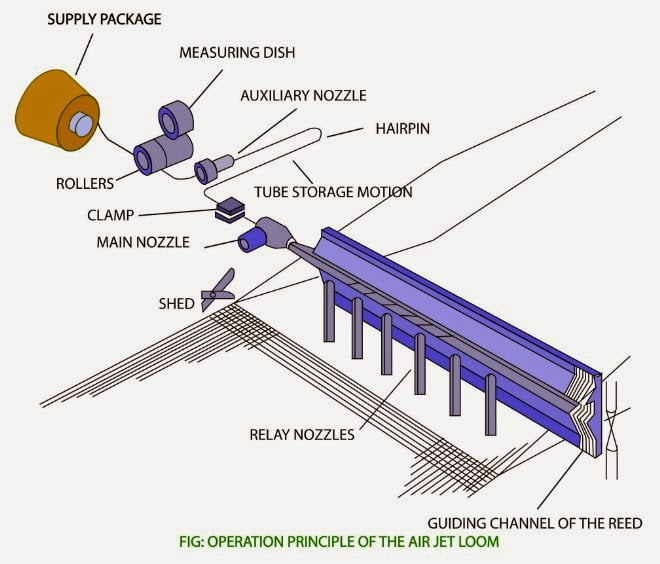

Operation Principle of Air Jet Loom

Last updated on August 29th, 2023 at 11:20 am

Working Principle of Air Jet Loom

Air jet weaving machines were invented in Czechoslovakia and later refined by the Swiss, Dutch, and Japanese were designed to retain the tension less aspect of the picking action of the water jet while eliminating the problems caused by the use of water.

The yarn is pulled from the supply package at a constant speed, which is regulated by the rollers, located with the measuring disk just in front of the yarn package. The measuring disk removes a length of yarn appropriate to the width of the fabric being woven. A clamp holds the yarn in an insertion storage area, where an auxiliary air nozzle forms it into the shape of a hairpin.

The main nozzle begins blowing air so that the yarn is set in motion as soon as clamp opens. The hairpin shape is stretched out as the yarn is blown into the guiding channel of the reed with the shed open. The yarn is carried through the shed by the air currents emitted by the relay nozzles along the channel. The initial propulsive force is provided by a main nozzle. Electronically controlled relay nozzles provide additional booster jets to carry the yarn across the shed. The maximum effective width for air-jet weaving machines is about 355 cm. At the end of the each insertion cycle the clamp closes; the yarn is beaten in, and then cut, after the shed is closed. Again some selvage-forming device is required to provide stability to the edges of the fabric.

These weaving machines use a jet of air to propel the weft yarn through the shed at rates of up to 600 ppm. Date from manufacturers indicate that air-jet looms operate at speed up to 2200 meters of pick inserted per minute. They can weave multicolored yarns to make plaids and are available with both dobby and jacquard patterning mechanism.

Air jet weaving is more popular because the machines cost less to purchase, install, operate, and maintain than rapier or projectile weaving machines, and the air jet can be used on a broader variety of yarns than a water jet.

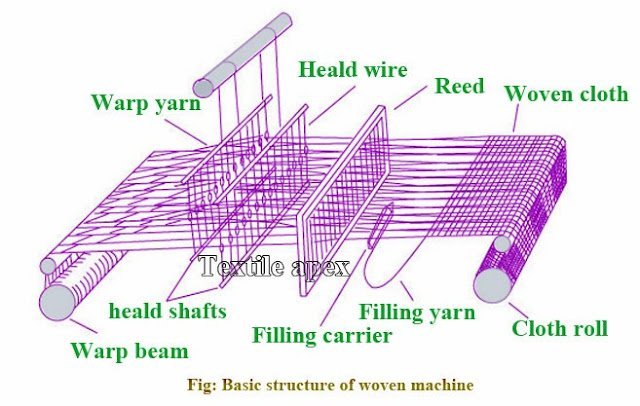

You may also like: Different Parts of a Loom

Nice article as well.

Hello Md,

Nice article!

I live in Halifax, West Yorkshire – the old weaving capital of the world and used to work various very old basic textiles machines but never saaw an airjet and I could not understand how a jet of air coudl carry the weft so far across the warps until seeing this explanation from you.

I've build an airjetloom myself in my little shed in the garden. https://youtu.be/DfRY1UrzqyQ

we are manufacturer factory in producing airjet loomso you can add my Skype ID : aaaaaa18885 and whatsapp ID is : 0086 15153684622 and my email is : williamgeorgebusiness@gmail.com then I will send the detail specification and bottom price and our product's video to you .we are factory , good quality, cheaper price .

Hi can you send your contact details to prasad4416@gmail.com