Different Types of Yarn or Thread Packages

Last updated on September 28th, 2023 at 09:21 pm

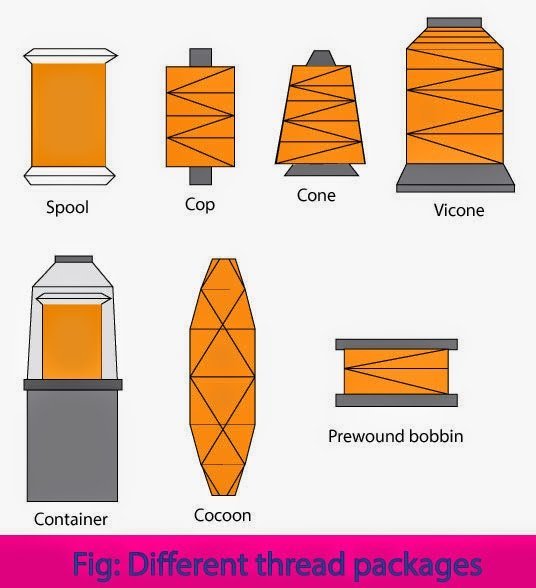

Sewing threads are put up on different types of thread packages called spools, cops or tubes, cones, king tubes or vicones, containers, cocoons, and pre-wound bobbins to suit different types of threads, machines, and sewing needs. Sewing machines require specific types of thread packages in order for the thread to be presented correctly to the machine. Thread packages may be color coded by size and type of thread to assist operators in correct thread section. Thread is sold by length instead of weight. The following figure shows several types of thread package:

Spools

Spools contain relatively short yardage and have thread wound in a parallel position. Spools have a flange either end that interferes with off winding on industrial machines. Spools are designed for home sewing use.

Cops

Cops are used primarily on lockstitch machines where a variety of colors are used and productions runs in any one color are short. Thread is cross-wound on cops or small tubes to increase in off winding.

Cones

Cones are symmetric, tapered forms made of paper or plastic that hold over 5,000 meters of cross-wound thread. Cones provide good off-winding performance for high-speed machines. Cones are the most economical packages for sewing threads in situations when thread consumption is high and production runs are long with limited shade changes.

Vicones or King Tubes

Vicones or king tubes may be parallel tubes or low-angle cones with a flange at the bottom, which is designed to contain spillage of smooth or continuous filament threads during of winding.

Containers

Containers are designed to handle lively monofilament threads that may be difficult to control with traditional packages. Very large spools of thread may have lubricant applied as the thread is off-wound.

Cocoons

Cocoons are centerless thread packages designed for insertion in shuttleless of multi-needle quilting machines and some types of embroidery machine.

Pre-wound Bobbins

These are precision-wound packages designed to replace metal bobbins in lockstitch machines. Generally, more thread is available and the length is more consistent on pre wound bobbins than on operator wound bobbins. Downtime is minimized by eliminating time for winding bobbins. Off winding is also improved because of precision winding. Pre wound bobbins are available in different thread types and sizes for different models of machines.

You may also like: What is Yarn: Definition and Meaning

Very educational.