Functions of Cone Drum, Flyer, Bobbin Tapper and Differential Motion

Last updated on October 18th, 2023 at 11:47 am

Cone Drum

As each layer of roving is added to the bobbin in the speed frame, its diameter is increased. In flyer leading and bobbin leading frame, it is necessary to increase or decrease the bobbin rpm respectively to maintain a constant surface speed on the bobbin surface as each layer is added to its diameter so that the delivered roving can be wound on the bobbin always at a constant rate. For this purpose bobbin speed is increased or decreased by moving the belt on the cone drum. Top cone drum is driver and bottom cone drum is a driven one. Bobbin driving shaft is connected with bottom cone drum. In case of flyer leading or bobbin leading frame, the belt on the top cone drum is moved a short step from smaller to larger diameter or larger to smaller diameter to increase or decrease the bobbin rpm respectively.

Flyer

The functions of the flyer are as follows:

Twisting and winding

The roving delivered by the front roller is twisted by the flyer. The flyer being driven by the spindle is projected through the center hole of the bobbin. As the strand of fibres held by the front roller at one end and the flyer is revolved with the strand round the bobbin at a different speed so, twisting and winding take place.

Building

It guides the roving through central hole of the flyer top and a eye at the flyer gives pressure to a specific place on the bobbin so that, successive coils are wound on the bobbin without lapping throughout the build of the bobbin package. The pressure of the flyer applies a certain amount of tension to the roving as to build a firm bobbin.

Bobbin Tapper

The function of the bobbin tapper is to produce conical shape of the bobbin being built up at both ends. As the bobbin build up progressively its lift is shortened at each reversing of the bobbin rail.

Differential Motion

Differential motion transmits motion from the bottom cone drum to the bobbin with increasing diameter of the bobbin with the regular change in speed with the instant movement of the belt on the cone drum. Thus the roving can be wound on the bobbin without stretching or slackness. This motion acts as a media to transmit the changing (increasing or decreasing for flyer leading or bobbin leading frame respectively) speed of the bottom cone drum to the bobbin in a steady manner with the changing of bobbin diameter and moment of belt on the cone drum.

You May also like:

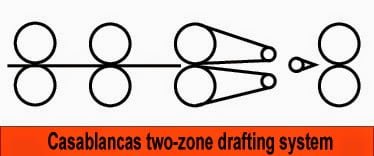

1. Classification of Drafting System in the Ring Frame | Explanation of A Modern System

2. What Are The Functions Of Ring, Traveller, Creel, Spindle, Roving Guide and Lappet Motion?

I have to voice my passion for your kindness giving support to those people that should have guidance on this important matter.