Basic Ingredients of Printing

Last updated on July 16th, 2023 at 12:46 am

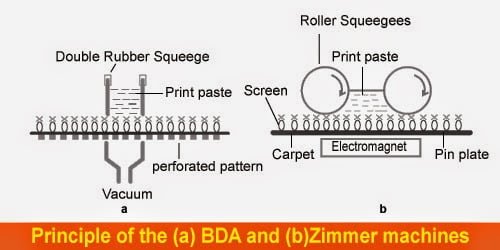

Printing is the process where the print paste is applied on the subjected fabric or garment swatch or whole garment to create printed patterns or designs. In this process, colourful patterns and designs are created that give a new look to the fabric and clothing. It can be done manually or by machine methods. There are different types of printing techniques like block printing, screen printing, digital printing, offset litho printing, etc. are available. During printing different types of basic ingredients like dyestuffs, thickeners, swelling agents, solvents, etc. are needed. In this article, we will know about the basic ingredients of printing.

The Basic Ingredients of Printing

- Dyestuffs and pigments

- Thickener

- Acid or alkali or acid liberating agents

- Carrier or swelling agents

- Solvents or solution acids or dispersing agents or humectants

- Antifoaming agents or de-foaming agents

- Wetting agents

- Catalyst or oxygen carrier

- Oxidizing and reducing agents

Dyes or dyestuff may be defined as colourants in which the colouring substance is dissolved in liquid, is absorbed into the material to which they are put in an application.

Pigments consist of excellent particles of ground colouring matter suspended in liquid which forms a paint film that bonds to the surface it is applied to.

Thickener

Thickener is a thick mass that imparts stickiness and plasticity to the print paste to be applied on the fabric surface without bleeding or spreading and capable of maintaining the design out lines.Thickener gives the required viscosity to the printing paste; prevents premature reactions between the chemicals in the print paste.

Acid and alkalis

Acid: Organic acid

Alkali: Sodium and potassium hydroxide, sodium carbonate, potassium carbonate etc.

These control PH and fix dye on the fabric.

Carriers and swelling agents

These accelerate the rate of dye penetration by fibre polymer, swell the fibre and reduce crystallinity.

Swelling agents: Resorcinol, phenol, polyethylene glycol etc.

Carrier: Diphenyl

Solvents or solution acids or dispersing agents

This prevents aggregation of the dyestuff molecules in the highly concentrated paste of the dye; solution aids increase the solubility of insoluble dyestuff, solvents increase the prints’ colour value, assist dye penetration and helps to get a bright design. Ex: Diethylene glycol, acetin, urea, glycerine etc.

De-foaming agents

De-foaming agents prevent the formation of foam during printing. E.g. silicone defoamers, sulphated oil etc.

Wetting agents

Substances that reduce the surface tension of water, thereby allowing it to wet a surface easily, which are otherwise non-wettable, are known as wetting agents or surface-active agents, e.g. TRO, olive oil, castor oil etc.

Catalyst or oxygen carrier

These prevent fibre damage during steaming; accelerate the final colour development by oxidation. E.g. Potassium ferrocyanide, copper, sulphide etc.

Oxidizing and reducing agents

Oxidizing agents develop final colour in steaming or in the subsequent after treatment, assist in colour fixation etc., e.g. sodium chlorate, potassium chlorate, sodium nitrite etc.

Reducing agents destroy the colour of the fabric. E.g. sodium hydro-sulphite, stannous chloride etc.

i read your post such a knowledgable post.