What is Beam Warping | What is Creel | Types of Creel

Last updated on August 21st, 2023 at 10:52 am

Definition of Beam Warping

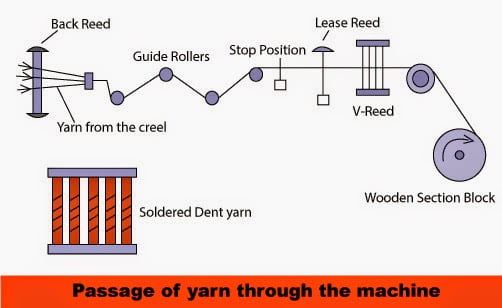

The warping process is intermediate between the winding and sizing processes. It produces the warper beams that are combined together as a single weavers beam in the next process of sizing. A warper beam may contain about 500-1000 warp ends. The direct or beam warping is suitable only for grey or monocoloured warps that require sizing. It involves only one operation namely warping and hence the speed and production are considerably higher than the sectional. The machine consists of a creel, a headstock, and control devices.

Definition of Creel

The creel is a stand for holding the supply packages in the form of wound packages. It enables to hold the supply packages in proper position for warping and constitutes an important component of the warping machine. No individual type of creel can be suitable for all types of yarn, counts, set lengths and different applications. In other words no single type of creel can give the same beaming efficiency for different types of yarns or applications. Hence different types of creels are to be used for different purposes. The creels used in warping are of the following types:

- V-Creel

- Rectangular

- Truck

- Continuous chain

- Magazine

- Automatic and

- Special creels

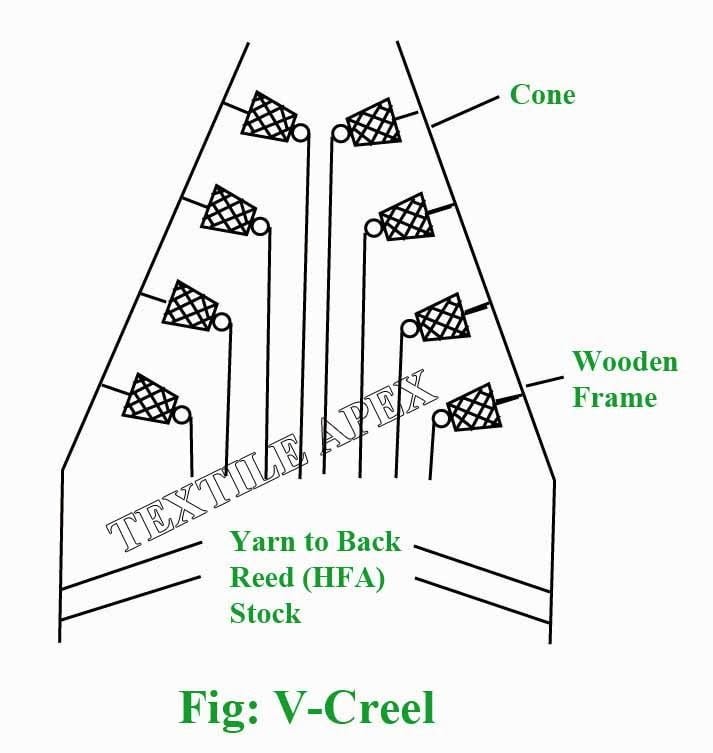

V-Creel

As the name implies, the type of creel is V-shaped. It consists of wooden pegs horizontally to hold the supply packages. This is arranged so that the apex is in line with the centre of the machine. The arm of this V-shaped wooden frame diverges on both sides from its apex.

This arrangement enables the ends to be withdrawn easily from the supply package without touching or getting entangled with one another during passing to the back reed of the head stock of the machine.

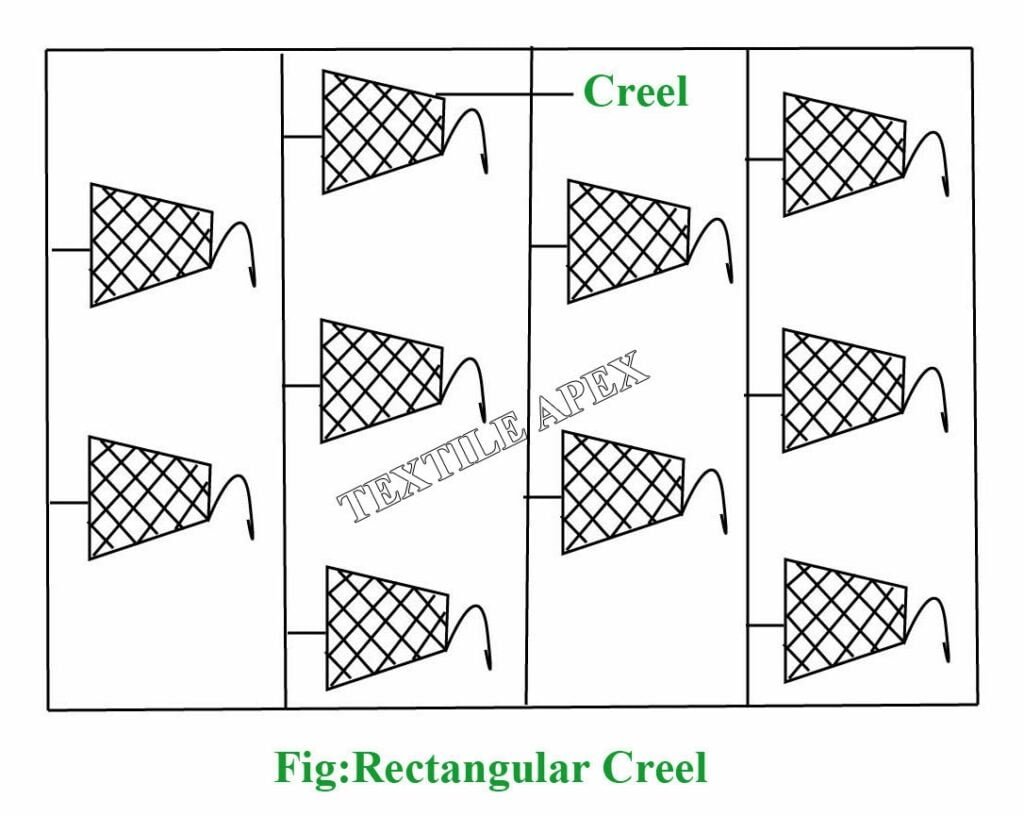

Rectangular Creel

This is rectangular in shape and hence its name. The frames are provided with pegs to hold supply packages horizontally. The frames can be increased to accommodate more number of supply packages vice versa. Each frame consists of thread guides, indicator lamps etc. It is mostly used in the slow speed warping machine.

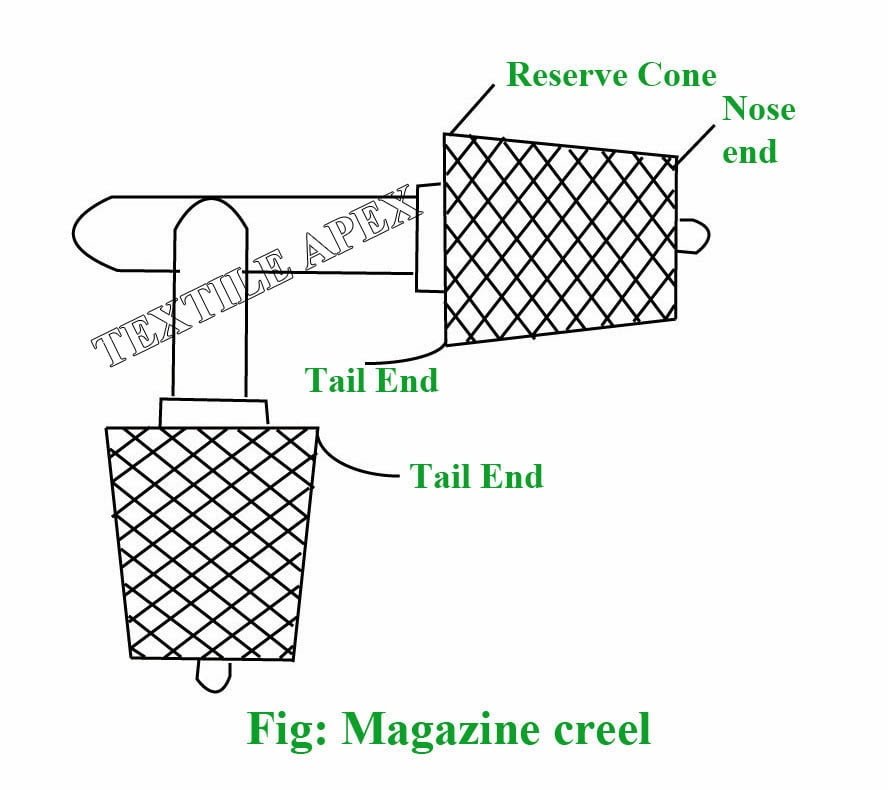

Magazine Creel

This provides with arrangements to hold reserve package. The tail end of the running package is knotted with the starting end of the reserve package. This enables the continuous working of machine without stoppage for replacing the exhausted package with a new one. The dimension of the creel and floor space required is comparatively more than other types of creel. The creel is usually V shaped.

Good article as well….

Best of luck, Bro..:)

Thanks for your comment…@ Imran Masud

where single end creel and travelling package

Needed to compose you a very little word to thank you yet again regarding the nice suggestions you’ve contributed here.