Types of Polymer | Requirements of Fibre Forming Polymer

Last updated on August 30th, 2023 at 12:26 am

A polymer is like a giant molecule of small building blocks called monomers. These monomers are tiny organic compounds. They form a long chain or network when they come together through a chemical process called polymerization. This can happen in different ways, like addition polymerization, where the monomers join without producing any extra stuff, or condensation polymerization, where they make a polymer and release small molecules as leftovers.

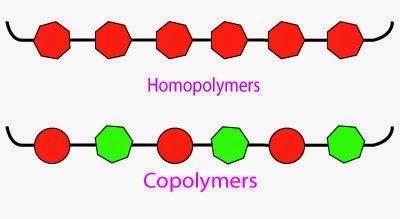

Different Types of Polymer

Homo-Polymer

Such a polymer is polymerized from the same or only one kind of monomer. Some homo-polymer fibres are nylon 6, nylon 11, polyethylene, polypropylene, polyvinyl chloride, and poly-acrylonitrile.

Copolymer

Such a polymer is polymerized from two or more different monomers. There are four sub-categories of copolymers, as follows –

- Alternating copolymer.

- Block copolymer.

- Graft copolymer.

- Random copolymer.

Requirements of fibre Forming Polymer

Fibre forming polymers should be –

- Hydrophilic

- Linear

- Long

- Capable of being oriented

- Chemically resistant, and

- Able to form high melting point polymer systems.

A Brief Explanation

Hydrophilic Properties

Fibre forming polymers should be hydrophilic. The polymers should be polar, enable them to attract water molecules. Fabric will be comfortable if its polymer system consists of hydrophilic polymers, and the system itself permits the entry of water molecules.

Linearity

Fibre polymers should be linear i.e. the polymers should not be branched. Only linear polymers allow adequate polymer alignment to bring into effect sufficient inter-polymer forces of attraction to give a cohesive polymer system and, thus resulting in useful textile fibre.

Length

Fibre polymers should belong. The length of the polymers constituting the commonly used fibres is in excess of one hundred nanometers. Polymers of such length can readily be oriented. If the polymers are oriented then there are sufficiently effective inter-polymer forces of attraction to form a cohesive polymer system, and hence, useful fibres.

Orientation

Fibre polymers should be capable of being oriented. The polymers can be arranged into more or less parallel order in the direction of the longitudinal axis of the fibre or filament.

Chemical Resistance

Fibre polymers should be chemically resistant for a reasonable length of time against the common degrading agents such as sunlight and weather, common types of soiling, laundry liquors and dry cleaning solvents. Another most important the requirement is then chemically resistant polymers should not be toxic or hazardous to wear against human skin.

Formation of High Melting Point Polymer Systems

A fibre consisting of high melting point polymer system tends to have adequate heat resistance to enable it to withstand the various heats treatments of textile wet processing, apparel manufacture and the heat subsequently applied to it during laundering, pressing or ironing during its useful life as a garment.

A fibres melting point needs to be above 225oC, if it has to be useful for textile manufacture and apparel use.

You may also like: Polyester Fibre Production Process and End Uses

Your good knowledge and kindness in playing with all the pieces were very useful. I don’t know what I would have done if I had not encountered such a step like this.

Your articles are extremely helpful to me. May I ask for more information?