Why the Simplex/Roving Frame is a Necessary Evil

Last updated on September 23rd, 2023 at 11:57 pm

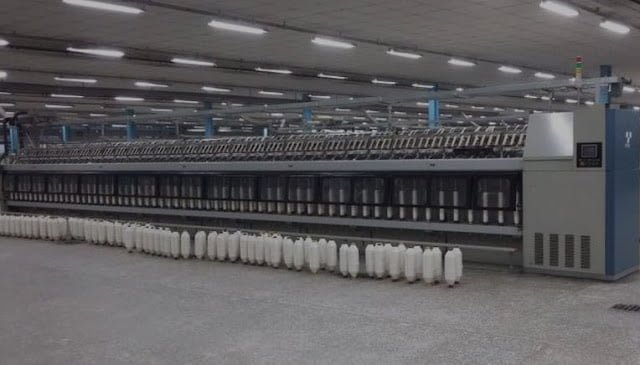

The simplex or roving frame is a modern form of speed frame. It is also known as fly frame. It is capable of imparting higher draft to material (up to 25). One of the noticeable features of this m/c is to absence of sound & noise. The higher speed of this m/c (spindle speed about 1500 r.p.m) results in increased production up to 50%. It also offers higher output package capacity.

Draw frame produce a sliver which have all the features for creating a yarn such as an orderly, clean strand of fibres lying parallel to each other. But this sliver is not used as feed material in ring spinning frame.

In fact, the roving machine is a complicated one, liable to faults, causes defects, adds to production costs and delivers a product that is sensitive in both winding and unwinding. Yet speed frame is used mainly for two major reasons:

- The first reason is to insert required draft to sliver. Drawn sliver is a thick and untwisted strand of fibre which needs 300~500 draft to be changed to yarn. But yet there is no machine to impart such great amount of draft to the sliver. Again if, this draft can anyway be imparted, the sliver will eventually break and create irregularity.

- The second reason is that, D/F can represent the worst form of material to feed in ring spinning frame.

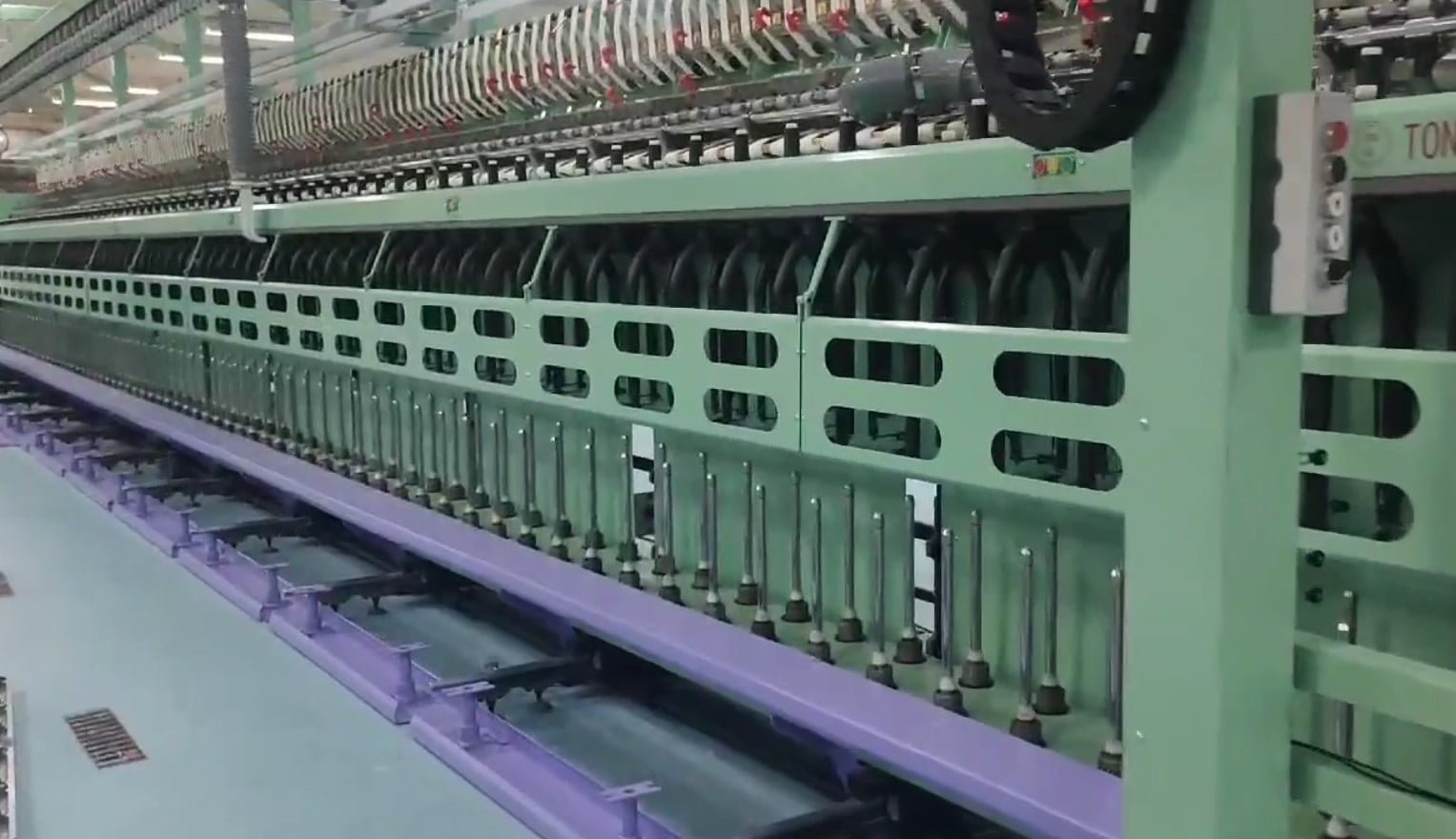

Moreover, if we consider the task of a roving frame/simplex, then we can see that it performs three main tasks:

- Attenuation (draft) of the sliver (the chief task).

- Insertion of twist to hold the fibres in the sliver &

- Winding the roving into a package that can be transported stored & feed to the spinning frame.

The third task has no contribution directly to spinning. Furthermore, it is the winding operation that makes the roving frame a relatively complex and a trouble plugged m/c. This winding motion requires in addition to the spindle & flyer, a cone-drive transmission (or variable gear), a different gear and a builder motion.

Again, the twist inserted in the roving should be removed first in the next process prior to final attenuation which also adds further complication.

For this reason, for years together the textile engineers are trying to subtract speed frame from spinning process, but still not fully successful. So, the speed frame is used as necessary evil.