With the evolution of the new concept of “Zero defects”, there is growing concern in the mills to control defects at every stage of manufacture. Lap defects can in the long run result in yarn defects, thus ultimately reducing the sale value of yarn. It is in this context that an understanding of the types […]

Essential Check Points in Blowroom

Given below are some checkpoints which will guide the technicians about some common deficiencies in the blow room and the corrective action to be taken in such cases with regard to quality control, maintenance or work practices. Mixing Room Opening and Cleaning Scutcher End Thus, if the technicians make it a point to inspect the […]

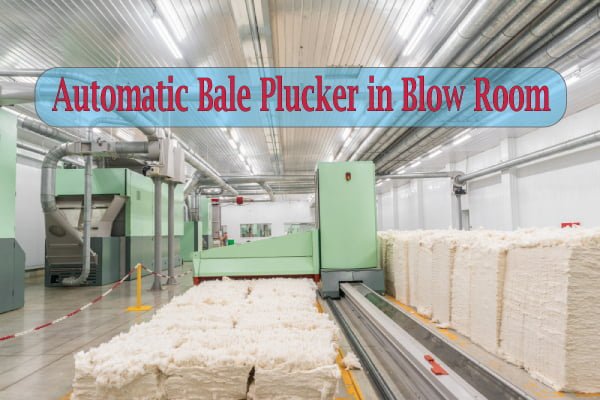

Blow Room: Definition, Objects and Process Layout

Blow Room The section where the supplied compressed cotton bale turns into a uniform lap of particular length by opening, cleaning, blending or, mixing is called blow room section. It is the first step of spinning. The section consist a number of different machines used in succession to open and clean the fibres. Objects of Blow […]

Mixing, Blending and Bale Management

Mixing Mixing could be thought of combining of fibres together in somewhat haphazard proportion whose physical properties are partially known so that, the resultant mixture has only generally known average physical properties which are not easily reproducible. Blending Blending is based on the measurement of important fibre properties i.e, length, strength, cleanliness, e.t.c. Quantitatively proportioning […]