Precautions Before Garments Dyeing

Last updated on February 21st, 2024 at 07:14 pm

At first garments dyeing technology applied on woolen and silk garments but now it is applied on polyester, acrylic, nylon and also extensively on cotton garments. Its popularity is increasing all over the world. There are many advantages of garments dyeing which are the reasons of its popularity increase.

Before garments dyeing some precautions are needed to avoid dyeing problems that may occur during garments dyeing. The precautions are discussed below:

- We have to design the garments and the design should be made from engineering point of view.

- There will be fewer problems if garment is made after desizing, scouring and bleaching of grey fabrics and then dyed in garments form.

- Grey fabrics lot and source should be same.

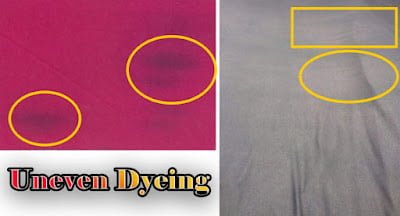

- Irregular dye penetration may be resulted due to too tight or too looseness of seams especially in the areas containing elastic like waistband, cuff etc.

- After garments dyeing seam pucker may develop if the knit fabric is not pre-shrunken when the garments are made from woven and knitted fabric combination.

- If the garment fabric is made from blended fibres, dye selection should be done very carefully during garments dyeing. Otherwise, irregular dyeing may be resulted.

- The accessories metal should be of good qualities. If we use poor metal, it may be damaged during dyeing by the action of salt and alkali. It is better to use the metals made from nickel or its alloy.

- Color difference may occur between garments fabric and sewing thread if the sewing thread fibre is not same as garments fabric.

- Buttons selection should be done very carefully. Because, casin, cellulose and nylon buttons may be damaged during garments dyeing. In this case, it is safe to use buttons made from polyester.

- Sometimes we have to use elastic in garments. If the elastic is made from natural rubber or polyurethane fibre like lycra may create great problem during garments dyeing. So dye should be selected properly to avoid such problem. The dye should be copper free.

- Interlining is a necessary part of a garment. We should use only those interlinings in the garments are recommended for garments dyeing. If not then the performance of the interlining will be destroyed.

- Problem of irregular dye penetration may occur if the garment made from compacted woven cotton fabric is not dyed with hot brand reactive dyes.

- If we use some specific dyes for some specific colors, then the dyeing cost will be lower. As for example, sulpher dyes produce navy-blue and black color at lower cost.

- Presence of mineral impurities in the cotton fibres may vary which may impede the stability of peroxide liquor during bleaching with hydrogen peroxide, even; insoluble compounds may form during hydrogen peroxide bleaching. Those insoluble compounds may redeposit on the garments fabric resulting spots on the fabric, special chemicals are available to avoid such problem.

- During dyeing of cotton garments crease marks may develop. Special chemicals like ‘Imacol brand’ may be used to avoid such problem.