Multi-Fibre Fabric: Definition and Types

Multifibre fabric is an integral part of textile testing and quality control. It is used on the face side or back side of fabrics, trims and accessories as adjacent fabric. It helps to assess depth of color staining from textiles with the help of a grey scale.

Multifibre fabric is generally used to perform different types of colorfastness tests such as colorfastness to water, sea water, perspiration, dye transfer, saliva, washing, dry cleaning, etc. There are different types of multifibre fabric such as DW, LW, multifibre-10 etc.

In this article, we will know the definition and types of multifibre fabric.

What is Multi-Fibre Fabric?

Multifibre fabric is a standard adjacent fabric containing at least six different textile fibres such as Diacetate, Bleached Cotton, Polyamide or Nylon, Polyester, Acrylic and Wool. Besides, some other fibres such as Regenerated Cellulose, Triacetate, Viscose and Silk are also used.

Most of the colorfastness tests are performed with the help of a multifibre fabric. After performing a specified test, color transfers from textile to multifibre adjacent fabric. Then the visual color assessment is done under D65 light source with the help of a Grey Scale.

Types of Multi-Fibre Fabric

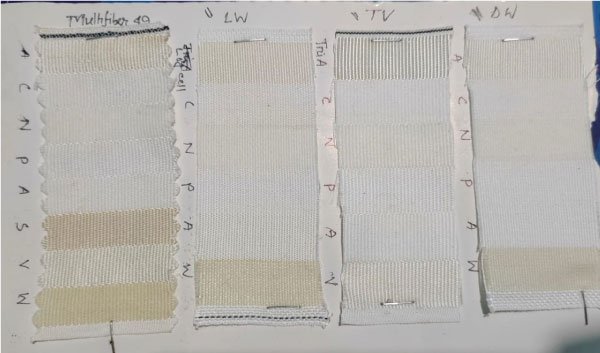

Primarily multifibre Fabric is classified into two main groups. One is for ISO standard such as DW, LW, etc. and another is for AATCC standard such as cold cut, heat seal etc.

Types of ISO Standard Multi-Fibre Fabric

There are three main types of ISO standard multifibre fabrics such as DW, LW and TV. These are mainly used to process the colorfastness tests for European Clients such as S. Oliver, Auchan, Wool Worth, Bestseller, Mother Care, Authentic Style, Benetton, Boux Avenue, CIA Hering, Cotton ON Group, Crew Clothing, Dicks Sporting Goods, Ernsting Family, Gymshark, ID IDENTITY, H&M, etc.

DW Multi-Fibre Fabric

Though it is used for testing samples of European Clients, it is also used to test samples of many American Clients such as Gap, Levi’s, American Eagle, The Children’s Place, etc. It contains the below six individual textile fibre strips:

- Diacetate

- Bleached Cotton

- Polyamide or Nylon

- Polyester

- Acrylic and

- Wool

LW Multi-Fibre Fabric

LW is used for some specific Clients like M&S, C&A, Next, Primark, Tesco, Asos and George. It contains the below six individual textile fibre strips:

- Regenerated Cellulose or Lyocell

- Bleached Cotton

- Polyamide or Nylon

- Polyester

- Acrylic and

- Wool

TV Multi-Fibre Fabric

It is mainly used for colorfastness to washing test for 600C and above temperature. It contains the below six individual textile fibre strips:

- Triacetate

- Bleached Cotton

- Polyamide or Nylon

- Polyester

- Acrylic and

- Viscose

Types of AATCC Standard Multi-Fibre Fabric

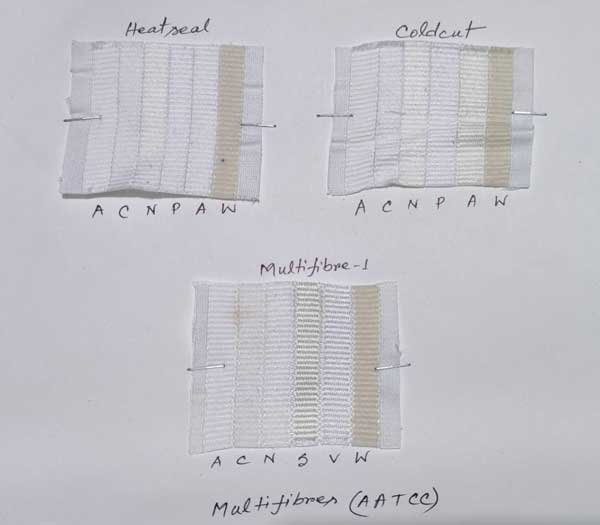

AATCC multifibre fabric is used to perform colorfastness tests for American Clients such as Carter’s, Bass Pro Shop, Express, Marks Work Wearhouse, Target USA, Walmart USA etc. There are three main types of AATCC standard multifibre fabric such as multifibre no. 10 (cold cut & heat seal), multifibre no. 1 and multifibre no. 49.

Multi-Fibre No. 10

Multifibre no. 10 is the most used multifibre to perform colorfastness tests for American Clients in AATCC method. There are two types of multifibre no. 10. One is cold cut and another is heat sealed. Cold cut multifibre no. 10 has no fused edges but the heat sealed has fused edges.

Heat sealed multifibre no. 10 is more expensive than the cold cut. Cold cut is used for testing AATCC water, perspiration, dye transfer etc. tests. But the heat sealed is used only for AATCC washing test.

It consists of the following six individual textile fibre strips:

- Filament Acetate

- Bleached Cotton

- Nylon or Polyamide

- Spun Polyester

- Spun Polyacrylic and

- Worsted Wool

Multi-Fibre No. 1

It is used for fabrics containing silk fibre only. Its edges are heat sealed. It consists of the following six individual textile fibre strips:

- Filament Acetate

- Bleached Cotton

- Nylon or Polyamide

- Silk

- Viscose and

- Worsted Wool

Multi-Fibre No. 49

It is used for some specific Client’s colorfastness test such as Dillard, Disney, etc. It consists of the following eight individual textile fibre strips:

- Filament Acetate

- Bleached Cotton

- Spun Nylon or Polyamide

- Spun Polyester

- Spun Polyacrylic

- Spun Silk

- Spun Viscose

- Worsted Wool