Maintenance of Dyeing Machinery

Last updated on July 18th, 2023 at 11:35 pm

The following features must be provided to run up a dyeing machine:

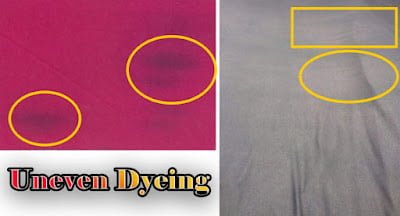

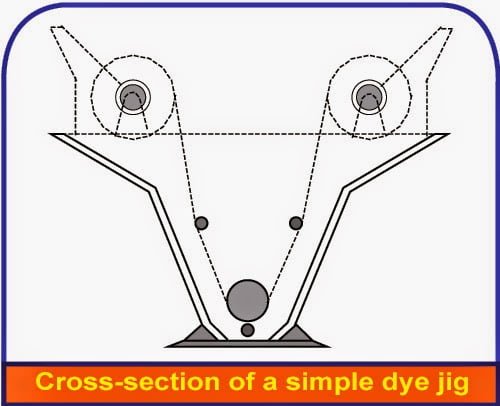

- It should provide sufficient movement for the liquor, dyeing to penetrate uniformly into every points of textile material.

- The machine must be constructed of such metal which will stay prolonged boiling, acid, alkali solution and other chemicals.

- The heating arrangement must maintain a uniform temperature everywhere of dye liquor.

- There should be the arrangement of adding the dyestuff solution in such a way that it becomes well mixed before it comes in contact with goods.

- All moving parts and electric motor should be protected against the corrosion by steam and atmospheric action.

- The machine must bear the largest possible outlet and inlet system.

- Some automatic temperature and pressure control devices should be assembled with the machine.

Besides the above all conditions, the dyeing machine may be hampered by using untreated water, chemical and dyestuff.

Effects of water

We must ensure that the used water is totally free from hardness. If we use hard water, it may cause chemical stain on machine. So, we should remove the hardness of water before use it.

Effects of chemicals

Used chemicals should be free from any impurity. Otherwise, textile good and machine both will be hampered.

Effects of dyes

Used dyes should be free from any impurity. Otherwise, textile good and machine both will be hampered.

Besides, we should take the following actions for proper running of the dyeing machine:

- Regularly clean up the machine.

- Clean the inner net regularly.

- Soft handle to machine.

- Monitoring the machine regularly.

- For any big problem, experts should be called.

Existing without the answers to the difficulties you’ve sorted out through this guide is a critical case, as well as the kind which could have badly affected my entire career if I had not discovered your website.