How to Identify Wool and Silk Fibre

Last updated on July 10th, 2023 at 11:30 pm

Recognition and identification of fibre content in fabrics has become extremely difficult even for knowledgeable and experienced merchants because of the growing variety of types of fibres, the blending techniques in yarn and fabric construction, and the finishes that affect the appearance and hand of the fabrics. Therefore, specific laboratory tests are used for identification and verification.

Now I will discuss the methods by which we can identify the Wool and Silk fibre:

Hand Feeling Test

The feeling test requires perception if it is to be of any value. Skilled perception is acquired only after handling different fabrics over a period of time. To understand what is meant by feeling a fabric, place your finger on a sample of wool. The heat generated by the finger remains in the area because wool is a non-conductor of heat. Consequently, the wool fabric feels warm to the touch.

Burning Test

To recognize the composition of fabrics by the burning test, the sample of fibre, yarn, or fabric should be moved slowly toward a small flame and the reaction to the heat should be carefully observed. One end of the sample should then be put directly into the flame to determine its burning rate and characteristics. After it is removed from the flame, the burning characteristics should continue to be observed, and the burning odor should be noted. After the sample has cooled, the ash should be examined for characteristics such as amount, form, hardness, and color.

Wool

It is slow to ignite burns with a characteristic smell, flickering flame, sizzles and curls. It can be extinguished easily, as the fabric ceases flaming when the fire is withdrawn. Wool ash is dark and crisp, and it falls into an irregular shape that can be crushed easily. The ash has a strong animal odor resembling burning feathers and hair, which indicates the presence of an animal substance or of a fibre obtained from an animal. The characteristic odor of burned wool is due to the sulphur in it.

Pure Silk

It burns slowly and ceases flaming when the fire is withdrawn. The ash of silk appears in the form of round, crisp, shiny black beads, like the ash of wool can be crushed easily with fingers. The ash has an animal odour less pronounced than that of wool, as silk does not contain sulphur.

In manufacturing, an additional body is given to silk fabrics by weighting them with metallic fillers. Weighted silk burns without showing a visible flame. The burned part becomes incandescent; it chars and gradually smoulders away, leaving coherent ash that is a screen-like skeleton of the original fabric. The odor of the ash of weighted silk is similar to that of pure silk.

Microscope Test

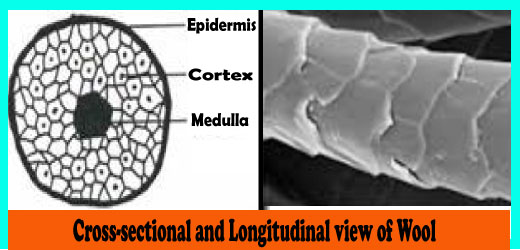

Wool Fibre

Wool fibre is irregular and roughly cylindrical, tapered at the end, and multi-cellular in structure. Under the microscope, a cross-section shows three fundamental layers – the epidermis, the cortex, and the medulla. The epidermis, or outer layer, consists of scales or flattened plates ranging from 1000 to 4000 to an inch. These scales give the fibre its cohesive quality. They vary in type; from those having smaller, finer scales with smoother edges to those having coarser scales with irregular edges.

The second layer, the cortex, is the main fibre body. It gives fibre strength and elasticity and consists of intermediate cells that hold the color pigment.

The innermost layer is the medulla which consists of large spiral-shaped, air-filled cells. The medulla is discernible only in coarse and medium wools and only under high magnification. It is the central canal, varying in appearance from a narrow to a broad line or from a continuous to an interrupted line. Some wool fibres that have no cortical layer are compensated with a large proportion of medullary cells.

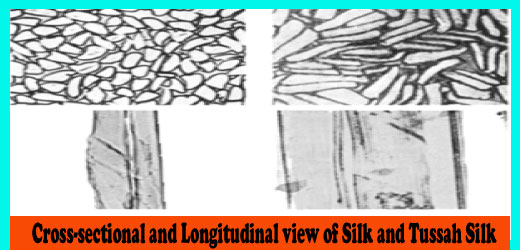

Silk Fibre

Silk fibre as it comes from the cultivated cocoon is called bave. Under the microscope, this bave appears somewhat elliptical. It is composed of fibroin, consisting of two filaments, each of which is called abrin, held together by sericin, a gummy substance that gives the bave a rather uneven surface. As the sericin is removed by the hot water, the two brin filaments appear clearly as fine and lustrous, somewhat triangular-shaped transparent rods.

Wild, or tussah, silk maybe distinguished from cultivated silk by its coarse, thick form, which appears flattened. Cultivated silk is a narrow fibre with no markings. Wild silk is a broader fibre with fine, wavy, longitudinal lines running across its surface, giving it a dark hue under the microscope.

Chemical Test

In addition to the microscope, chemical tests are another technical means of identifying fibres. But chemical tests are not intended for the general consumer. Their value is demonstrated, however, by the fact that some consumer magazines and commercial firms have their own laboratories for testing fabrics.

If the fibres in a sample are known to consist of silk and wool, and identification of each is desired, the use of concentrated cold hydrochloric acid will dissolve the silk and cause the wool fibre to swell.

Some us know all relating to the compelling medium you present powerful steps on this blog and therefore strongly encourage contribution from other ones on this subject while our own child is truly discovering a great deal. Have fun with the remaining portion of the year.

whoah this blog is excellent i really like reading your articles. Keep up the good work! You know, many people are looking round for this information, you can aid them greatly.

I all the time used to read piece of writing in news papers but

now as I am a user of internet so from now I am using net for articles, thanks to web.