How to Identify Rayon and Acetate Fibre

Last updated on July 10th, 2023 at 10:54 pm

Recognition and identification of fibre content in fabrics has become extremely difficult even for knowledgeable and experienced merchants because of the growing variety of types of fibres, the blending techniques in yarn and fabric construction, and the finishes that affect the appearance and hand of the fabrics. Therefore, certain laboratory tests are used for identification and verification. Now I’ll discuss how to identify Rayon and Acetate fibre:

Burning Test

Rayons

Like cotton, the rayons ignite quickly unless they either are fire-retardant types or re given a fire-retardant finish. They burn with a bright yellow flame, sometimes more rapidly than cotton because rayons are essentially purified cellulose. The odor of burning viscose and high wet-modulus rayons is like that of burning paper, also a cellulose product. The ash disintegrates unless the fibre has been chemically dulled.

Acetate

It blazes as it burns. The edge of the fabric puckers and curls as the material fuses and melts into a hard mass. It sputters and drips like tar. The ash of acetate is hard and brittle, and is difficult to crush between the fingers. Because of the acetic acid used in the manufacture of acetate, the ash has an acid odor similar to that of vinegar.

Microscope Test

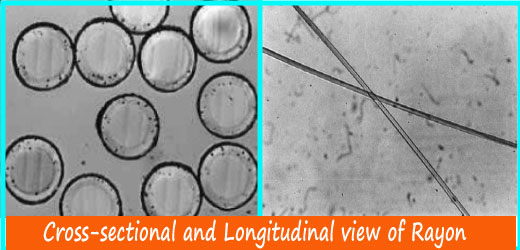

Rayons

Basically, these fibres have a glasslike luster under the microscope and appear to have a uniform diameter when viewed longitudinally. The appearance of fine paper like particles on a cross-sectional view is an indication that the rayon has been delustered.

Viscose rayon has a cross-sectional view under the microscope that is very irregular. These irregularities or wrinkles run the length of the fibre and appear as striations or fine lines in the longitudinal view on an otherwise glossy surface. The rayon filaments differ in appearance according to the process used in their manufacture. Some may have a cross section that is somewhat flat and irregular or on the other hand, have a dough nut like cross section.

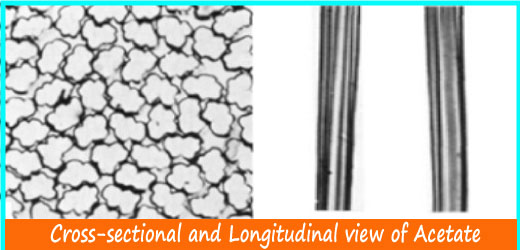

Acetate

The cross-section view of acetate fibre is less irregular than viscose rayon; it has a bulbous or multilobular appearance with indentations. These indentations appear as occasional markings or striations in the longitudinal view. The cross-section can be regulated during the manufacturing process to produce various shapes to affect the appearance and hand of the fibre.

Chemical Test

A solution containing equal parts of concentrated sulfuric acid and iodine may be used to distinguish each of the different fibres. When samples are immersed in this solution, a dark-blue coloration indicates viscose; a yellow coloration indicates acetate. Another test to distinguish acetate from rayon, when both types are known to be used in a fabric, is to immerse the sample in a 50% solution of acetic acid. The acetate dissolves; the rayons are not affected. All rayons will dissolve in a 60% solution of sulfuric acid or a concentrated solution of hydrochloric acid.

You may also like: How to Identify Wool and Silk Fibre