Garments Efficiency Calculator: Calculate Efficiency in the Garment Industry

Garment Production Efficiency Calculator

Total Minutes Produced: 0

Efficiency Percentage: 0%

Production Target per Hour (@100% Efficiency): 0

Comparison with Target Production: 0%

Line Efficiency (if applicable): 0%

Are you struggling to measure your garment production efficiency? Do you want to optimize your factory’s performance and meet production targets effortlessly? You’re in the right place! Introducing the Garment Production Efficiency Calculator – a simple, powerful tool designed to help you track and improve your production processes.

What is Garment Production Efficiency?

Garment production efficiency measures how effectively your factory converts labor and time into finished products. It’s a key metric for any garment manufacturer aiming to reduce waste, save costs, and meet deadlines. But calculating efficiency manually can be time-consuming and error-prone. That’s where our calculator comes in!

Why Use the Garment Production Efficiency Calculator?

- Save Time: No more manual calculations. Get instant results with just a few clicks.

- Accurate Results: Ensure precision in measuring efficiency, production targets, and line performance.

- User-Friendly: Designed for everyone – from factory managers to production supervisors.

- Free Tool: No downloads or subscriptions required. Use it anytime, anywhere.

How Does the Calculator Work?

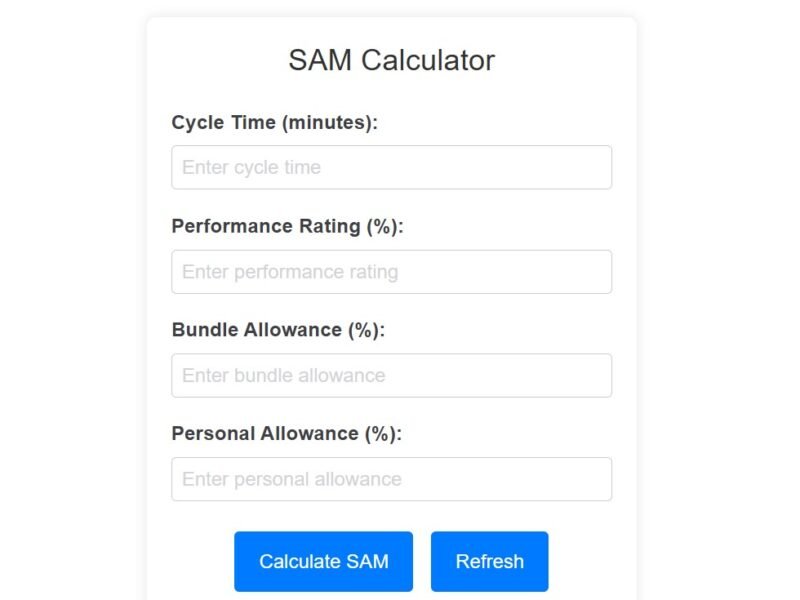

The calculator uses industry-standard formulas to provide accurate results. Here’s what you need to input:

- Number of Garments Produced: Enter the total garments your team produced.

- Standard Time per Garment (SAM): Input the time (in seconds) it takes to produce one garment.

- Total Hours Worked: Add the total hours your team worked during the shift.

- Target Production (Optional): Set your production target to compare actual performance.

- Number of Operators (Optional): Enter the number of operators to calculate line efficiency.

Once you input the data, the calculator will instantly show:

- Total Minutes Produced

- Efficiency Percentage

- Production Target per Hour

- Comparison with Target Production

- Line Efficiency (if applicable)

Example Calculation

Let’s say your team produced 400 garments with a SAM of 30 seconds and worked for 8 hours. Here’s what the calculator will show:

- Total Minutes Produced: 200 minutes

- Efficiency Percentage: 41.67%

- Production Target per Hour: 2 garments

- Comparison with Target Production: 88.89% (if the target was 450 garments)

- Line Efficiency: 4.17% (if 10 operators were working)

Tips to Improve Garment Production Efficiency

- Train Your Team: Skilled workers perform tasks faster and with fewer errors.

- Optimize Workflow: Arrange workstations to minimize movement and delays.

- Use Technology: Invest in tools like this calculator to track and analyze performance.

- Set Realistic Targets: Use SAM and efficiency data to set achievable goals.

- Monitor Regularly: Track efficiency daily to identify and fix issues quickly.

Final Thoughts

Efficiency is the backbone of successful garment production. With the Garment Production Efficiency Calculator, you can easily measure, analyze, and improve your factory’s performance. Start using it today and see the difference it makes in your production process!