Changes to be Made in a Speed Frame when a Certain Hank is Made Finer

Last updated on October 18th, 2023 at 11:51 am

Suppose, a certain hank is made on a machine and it is desired to change to a higher count. The same sliver or roving is used in the creel. The necessary changes are as follows:

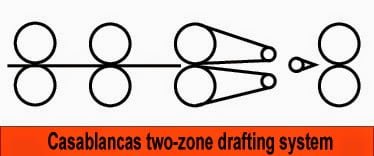

Draft: This must be altered in order to make the delivery roving finer. The draft change pinion (D.C.P) will therefore be made smaller in order to drive the back roller more slowly.

Lifter change wheel: A smaller lifter change wheel slows down the lifter shaft without altering the bobbin speed and thus decreases the spacing of the coils.

Ratchet wheel or Spur wheel change building motion: The finer roving also requires that the ratchet wheel should be entangled (i.e. greater no. of teeth) in order that a lessened movement be given to the rack at each up & down lift. There will be more layer/inch of diameter for the finer than for the coarser roving, therefore each action of the lift must give a shorter traverse to the rack which moves the cone drum strap in short steps.

With the spur-wheel change build motion, a finer hank will require either a larger wheel in the top position or a smaller wheel in the bottom position.

Bottom cone-drum change or winding wheel: A smaller wheel (if it is driver one) will be required to correct winding on the bobbin as the front roller delivery will be less for the finer hank.

Twist change pinion: A finer roving requires more twist/inch into it than a coarser one. Twist wheel is changed for this purpose and by making it smaller, the speeds of the front roller is reduced but since the speed of the spindles is not altered, more twist will be put into the roving.

From this change, it will be noticed that the speed of the cone drum is also changed, which is a necessary consequence of changing of the speed of the front roller to slow, the bobbins must have the same reduction in the speed in order to wind on the smaller amount of roving that is delivered to them.