Breaking Strength and Elongation of Textile Fabrics: Grab Test (ASTM D5034)

Last updated on September 18th, 2025 at 07:52 pm

Scope

To determine the effective strength of the fabric in use that is the strength of the yarns in a specific width together with the additional strength contributed by adjacent yarns.

Definitions

- Grab test a tensile test in which the central part of the width of the specimen is gripped in the clamps.

- Tensile strength of a yarn or fabric is defined as a maximum load that it will endure without breaking when subjected to uni axial tensile loading.

Apparatus and Equipment

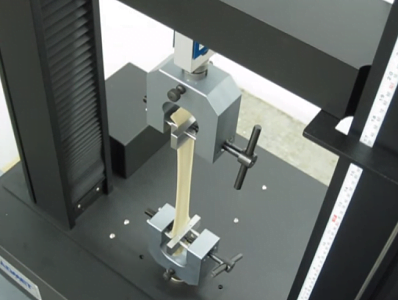

- Constant rate of extension machine (CRE): With operation at a speed of 300 ± 10 mm/min (12 ± 0.5 in/min). Fabric tensile test machine provides you higher testing accuracy.

- Each clamp shall have a front (top) jaw face measuring 25 ± 1 mm (1.0 ± 0.02 in.) perpendicular to the direction of the application of the force and shall be 1.0 in. x 1.0 in. rubber coated jaws parallel to the direction of the application of the force.

- The back (bottom) jaw face of each clamp shall be 1.0 in. x 2.0 in. coated jaw.

Sample Preparation

- Three lengthwise specimens and three width wise specimens are taken from each sample fabric.

- Each specimen 100 ± 1 mm (4 ± 0.05 in.) wide by at least 150 mm (6 in.) long is cut with the long dimension parallel to the direction of testing and force application. In general, no two specimens cut parallel to the warp should contain the same set of warp ends, and no two specimens parallel to the weft should contain the same weft yarns. Unless otherwise specified, do not cut specimens closer than 1/10 of the width of the fabric from the selvedge.

- A line is drawn on the specimen, which is parallel to the long direction (and along a yarn of woven fabric) and located 37 ± 1 mm (1.5 ± 0.02 in.) in from the edge of one side of the specimen.

Testing Procedure

- Dependent on the type of equipment used, and the software that is installed, the machine should be operated following the manufacturer’s guideline. If the machine is software equipped, select the appropriate program to run.

- The distance between the clamps (gage length) should be set at 75±1mm (3.0 +/- 0.05 in). NOTE: The force range of the testing machine for the break to occur should be selected between 10 and 90% of full-scale force.

- The specimen is mounted such that the longer dimension of the specimen is tested. One side of a specimen is placed in the upper clamp and locked in place. The side of the jaw has to be along the previously marked line. The clamping area must be approximately 1 in. from the top edge of the specimen.

- The other side of the specimen is placed to the lower clamp. A tension of approximately 0.37 lb force (not to exceed 0.5% of the full-scale load) is applied by pulling down the specimen. While the specimen is held taut the bottom clamp is locked.

- “START TEST” is pressed to start testing.

- Any break occurring within 5 mm (0.25 in.) of the jaws which results in a value below 50 % of the average of all the other breaks should be discarded. If a fabric manifests any slippage in the jaws or if more than 25% of the specimens break at a point within 5 mm (0.25 in.) of the edge of the jaw, modification of jaws can also be accepted. For example, the jaws may need to be padded; or the fabric may need to be coated under the jaw face area; or the jaw face may need to be modified etc. Those modifications should be stated in the report if applied.

Analysis of Data

- The average of observed breaking load and elongation is recorded directly from the machines or the computer for all acceptable specimens.