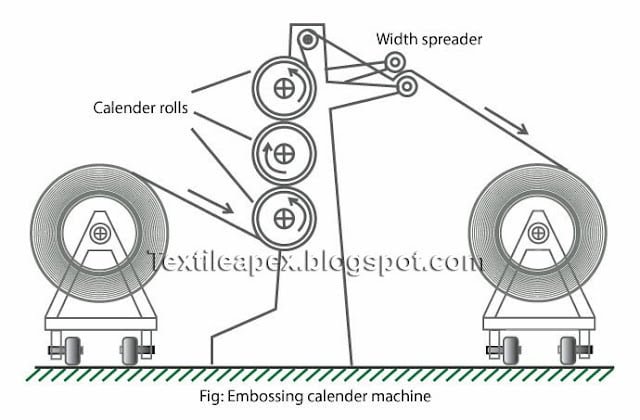

What is Calendaring | Working Procedure of Embossing Calendaring Machine

Last updated on August 23rd, 2023 at 11:48 pm

Definition of Calendaring

After a grey fabric is subjected to scouring, bleaching, mercerizing etc, it is finally dried to retain its true shape and dimensions. But in this state the fabric becomes least lustrous. Because of those operations the threads in fabric become wavy and crimped. But if a fabric is to appear highly lustrous then its surface should be perfectly flat and fibres appeared on the surface should be parallel to each other and all should lie in the length direction.

To fulfill this object cotton, linen, rayon, silk materials are applied a temporary physical finish which is known as calendaring. In this process fabric is passed through a series of heated rollers under pressure in open width form.

Objects of Calendering

The main objects or purposes are mentioned below:

- To cause a closing together of the threads of the fabric by flattening them and thus tending to fill up the interstices between warp and weft.

- To produce a smooth, glossy and highly lustrous appearance on the surface of the cloth.

- To reduce fabric thickness.

- To reduce air permeability and water permeability of fabric by changing its porosity.

Embossing Calendaring Procedure

Embossing is a particular calendaring process through which a simple pattern can be engraved on the cloth. The machine is made up of a heated and embossed roller made of steel pressed against another roller coated with paper or cotton. Its circumference is precisely a whole multiple of the metal roller. A gear system operates the coordinated motion of the rollers, preventing them from sliding and granting a sharp engraving of the patterned design. After being engraved, the pattern can be stabilized using appropriate high-temperature treatment or applying suitable starchy substances.

The process can be applied to fabrics made of all types of fibres, except wool. This finish is pretreatment when applied to fabrics made of thermoplastic fibres. It is not permanent when applied to untreated fabrics made of natural fibres or artificial fibres that are not thermoplastic; however, if these fabrics are treated with specific chemical resins, the embossing is considered pretreatment. To preserve the embossed finish of such fabrics, they should be washed in lukewarm water with a mild soap, never be bleached, and be ironed on the wrong side while damp.

Advantages

- Crepes or pebble effect can be produced.

- Temporary and permanent effect may be produced by different of pressure and heat.

- Due to smaller metallic bowl, cost is less.

- Generally used for synthetic fabrics. It cannot create any effect on cotton fabric.

You may also like: Different Types of Fabric Finishes

Nice image of calendering machine.

yh its so cool m9 i luv it bru….

Thanks for appreciating….

nice one

At this time, it seems like WordPress is the preferred blogging platform available right now. (from what I’ve read) Is that what you’re using on your blog? Great post, however, I was wondering if you could write a little more on this subject?