Direct Dye: An Overview [A to Z]

Last updated on October 6th, 2023 at 11:09 pm

Definition of Direct Dye

An anionic dye which have substantivity for cellulosic fibres, normally applied from an aqueous dye bath containing an electrolyte is known as Direct dye.

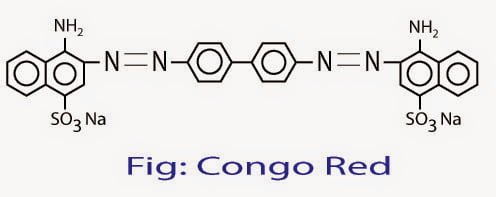

Chemical Structure of Direct Dye

Significance or Properties of Direct Dye

- It is soluble in water.

- It has sodium salt of sulphuric acid or carboxylic acid.

- It has strong affinity to cellulose fibre.

- Protein fibre can be dyed with this dye.

- Comparatively cheap.

- Easily diffusible into fibre.

- Wash fastness is not so good.

- The tinctorial power of this dye is very good.

Classification of Direct Dye

Based on migration test and salt control ability these dyes are classified as follows:

- Class – A (Self leveling)

- Class – B (Self controllable)

- Class – C (Temperature controllable)

Class – A

- Dyes migrate well.

- High leveling power.

- They may dye unevenly at first but further boiling will bring about even distribution.

Class – B

- Poor leveling power.

- Dye exhaustion must be brought about by controlled salt addition.

- If these dyes are not taken up uniformly in the initial stages, it is extremely difficult to correct the levelness.

Class – C

- These are not self leveling.

- Highly sensitive to salt.

- The exhaustion of these dyes cannot adequately be controlled by addition of salt alone and they require additional control by temperature.

Application of Direct Dye on Cotton Fabric

Typical Recipe

Dyestuff: 2%

Na2CO3: 2 – 3%

Wetting Agent: 1%

NaCl/Common Salt: 10%

M:L: 1 : 20

Temperature: 800 – 900 C

Time: 1 – 1.5 hrs

Dyeing Process

Dye Solution preparation

Mix dye with normal water and make dye paste; then pour hot water to dissolve the dye properly and ensure uniform bath concentration.

- The dye bath is set at 400C with substrate and required water level.

- Add wetting agent, sequestering agent, leveling agent, and other auxiliaries and run time 5 min.

- Add dye solution by linear dosing at 400 C and run time 10 min.

- Add soda ash by curve or progressive dosing at 400 C and run time 10 min.

- Temperature has to be raised up to 1000 C (20 C per min.) within 30 minutes.

- Salt dose is started before reaching the temperature at 1000 C and it continues till reaching 1000 C. It should dosed where exhaustion will be maximum.

- Dyeing is continued for 60 minutes at 1000 C.

- Cool down to 700C.

- Drop the bath, rinse and carry out after – treatment process to improve wet fastness.

After-treatment

The dyed material is carried out at 700Cfor 30minutes in a bath containing 1 to 3% of acetic acid (30%) and 1 – 3% of CuSO4 according to the depth of shade. It improves light and wash fastness.

Trade or Commercial Name of Direct Dye

| Name | Company Name |

| Durazol | ICI |

| Coprantine | Ciba Geigy |

| Solar | Sandoz |

| Chlorazol | ICI |

| Solophenyl | Ciba Geigy |

Factors Related to this Dye

- PH value: 9 – 10

- Temperature: 85 – 900 C

- Time: 1 – 1.5 hrs

- Effect of dye molecules size: 30 – 40 A0 (Always lower than the porosity of the of the fibre)

- M:L or effect of concentration: Less loss of the solution (For higher: light and for lower: deeper)

Identification of Direct Dye

At first we take 5 gm of colored sample which is provided by the buyer. Then we have to take a test tube with soap or detergent liquor. Then we will also take a white fabric and put both fabrics in the test tube. Then we have to heat it up to boiling point with a burner. After sometimes we can see that the colored sample is colorless and the white fabric becomes colorful. This may only happened for direct dye.

Why Direct Dye is So Called

These dyes are anionic and having substantivity for all type of cellulosic fibres such as cotton, viscose, rayon etc. These dyes have strong affinity towards the fibre which can be applied directly on the fibre and which do not need any assistance. These dyes have affinity for cellulose and therefore they are also substantive dyes. So, this dye is so called.

You may also like: Classification of Textile Dyes