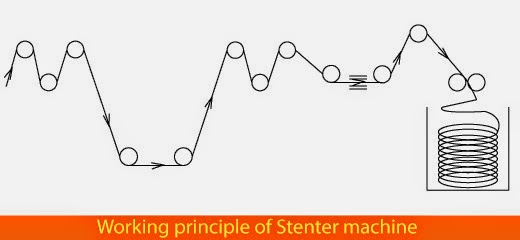

Working Principle of Stenter Machine

Last updated on July 18th, 2023 at 11:19 am

Stenter machine is not only a dryer but also used for many other purposes. Here knitted and woven fabric in open width form is treated. This multipurpose machine is used for the following purposes:

- Drying

- Heat setting

- Width control

- Curing

- Finishing chemical application

- Selvedge printing

- Uniform moisture control for pad batch dyeing

- Loop control

- Weft straitening

- Pigment dye application

- Any thermo fixation

- Padding mangle

Here finishing like OBA treatment, dry-cross finish, moist cross finish, wrinkle free finish, easy care finish can be done along with width and shrinkage control.

Working Procedure

Continuous drying is done in a stenter frame by convection. Blowers impinge hot air on both the top and bottom of fabric as the fabric passes through the chamber of the machine. Its frames are equipped with an endless chain on each side to grip the fabric by both selvages as it enters chamber. The distance between the chains can be increased or decreased. In every chamber there are burners and blowers. The temperature of each chamber can be controlled individually. The fabric gripping in stenter, two systems are available:

- Clip to grip coarse fabrics like twill fabric.

- Pin to grip fine fabric.

I feel really happy to have seen your webpage and look forward to so many more entertaining times reading here. Thanks once more for all the details.