Ultimate Guide to Washing Fastness Test Methods

In the textile industry, ensuring the durability and longevity of fabrics is of paramount importance. One crucial aspect of fabric quality is its ability to withstand repeated washing without significant color fading or damage. To determine the fabric’s resistance to washing, various test methods are employed, collectively known as washing fastness tests.

What is Washing Fastness?

Washing fastness refers to a fabric’s ability to retain its color, appearance, and structural integrity after being subjected to multiple washing cycles. It is an essential attribute for garments, ensuring customer satisfaction by maintaining the fabric’s original aesthetics and performance.

Importance of Washing Fastness Test Methods

Accurate testing of washing fastness is crucial for textile manufacturers, retailers, and consumers alike. It provides valuable insights into the fabric’s quality, helps determine appropriate care instructions, and aids in the development of superior products. Effective washing fastness test methods allow for the assessment and comparison of different fabrics, facilitating informed decision-making throughout the supply chain.

The Washing Fastness Test Methodology

Preparation of Test Specimens

Before conducting washing fastness tests, fabric specimens are prepared. This involves cutting representative samples from the fabric to be tested, ensuring they adequately represent the entire batch. The specimens are then carefully labeled for identification throughout the testing process.

Selection of Test Conditions

Washing fastness tests require the establishment of specific test conditions to simulate real-life laundering. Factors such as temperature, detergent type, agitation, and number of wash cycles are considered. These conditions may vary depending on the intended use of the fabric, such as home textiles or apparel.

Conducting the Washing Fastness Test

The prepared fabric specimens undergo the washing fastness test, which involves subjecting them to a series of washing cycles under controlled conditions. This process aims to mimic the wear and tear experienced by fabrics during regular laundering. The washing machine is programmed according to the predetermined test conditions, and the specimens are carefully loaded.

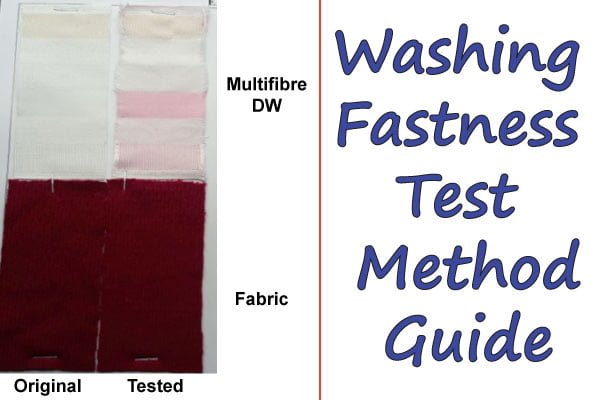

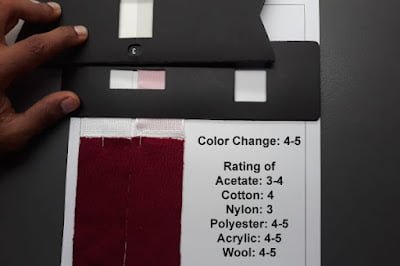

Evaluation of Test Results

After the completion of the washing fastness test, the fabric specimens are examined and evaluated for any color fading, staining, shrinkage, or physical damage. The evaluation may include visual inspection, color measurement using spectrophotometers, and comparison against predetermined rating standards.

Reporting and Interpretation of Results

Once the test results are obtained, they are documented in a comprehensive report. The report includes information about the fabric’s performance, adherence to relevant industry standards, and any recommendations for improvement. The results are interpreted by experienced professionals to provide meaningful insights for fabric manufacturers and consumers.

Benefits of Conducting Washing Fastness Tests

Washing fastness tests offer numerous benefits to stakeholders involved in the textile industry:

Quality Assurance

By conducting washing fastness tests, manufacturers can ensure the durability and longevity of their fabrics. This, in turn, enhances the overall quality of their products and builds trust with customers.

Compliance with Standards

Adhering to specific industry standards is crucial for textile manufacturers. Washing fastness tests help them comply with regulatory requirements and meet the expectations of their target markets.

Product Development

Washing fastness test results provide valuable insights for fabric developers. They can identify areas for improvement, optimize production processes, and create fabrics with enhanced washing durability.

Consumer Satisfaction

Garments or textiles that have undergone washing fastness tests instill confidence in consumers. Knowing that a fabric has been tested and proven to withstand repeated washing reassures buyers of its long-term performance.

Conclusion

In the ever-evolving textile industry, ensuring fabric durability is essential for success. Washing fastness test methods serve as a crucial tool in evaluating and comparing fabrics, providing valuable data for manufacturers, retailers, and consumers. By adhering to standardized washing fastness testing protocols, textile professionals can develop superior products, enhance customer satisfaction, and establish their brands as leaders in the industry.